About Vishva Spare Parts

15+ Years Experience VISHVA SPARE PARTS

At Vishva Spare Parts, we're your trusted supplier of spare parts for plastic bag and pouch making machinery. We cover a wide range of categories, including Converting Machines, Blown Film Plants, Slitters, Printing & Lamination, Recycling Lines, Consumables, Auxiliaries, and Lab Instruments. Our mission is to keep your machines running smoothly, so you can focus on what you do best.

We understand the importance of convenience, which is why we've launched our spare parts website. It's designed to cater to our clients in a seamless manner. Need specific parts or expert advice? We're here for you. Let's make sure your machinery never misses a beat. Reach out to us, and let's connect for your spare parts needs!

Best Sellers

-

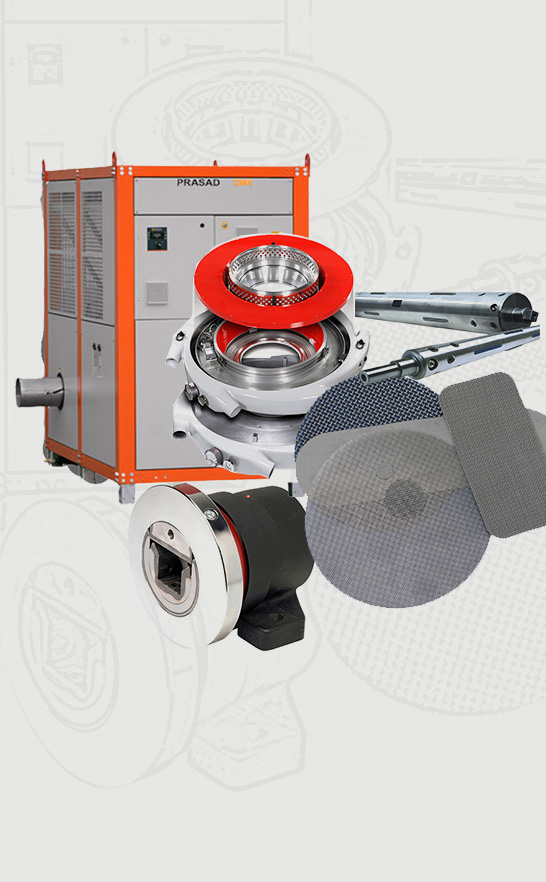

Air Shafts

Air Shafts are essential components in plastic converting machine testing. They provide a reliable and efficient method for securely holding and supporting rolls of plastic materials during unwinding and rewinding operations, ensuring smooth and controlled material handling for accurate and consistent converting results.

-

Hopper Loader

The Hopper Loader is used in extrusion machines. It enables automatic feeding of granules into the extruder hopper, ensuring a continuous and consistent supply of material for efficient and uninterrupted production in the extrusion process.

-

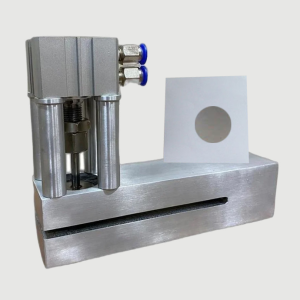

Hole Punch

A versatile tool for creating holes, the hole punch is essential for enhancing air circulation in various applications such as nursery bags and fruit bags. It promotes optimal ventilation, aiding in the growth and preservation of plants and fruits.

-

V Belts

V belts used in plastic converting machine testing. These specially designed belts offer excellent traction, high power transmission capabilities, and resistance to wear and tear. They ensure smooth and efficient operation while assessing the machine’s performance, stability, and reliability during testing.

-

Offline Punch Machine

The Offline Punches Machine in a plastic converting machine is a versatile tool that accommodates various punching operations, including the D-punch, hole punch, and t-shirt punch. It enables manufacturers to add custom shapes, holes, and unique designs to plastic materials during secondary conversion processes.

With the D-punch feature, the machine can create precise D-shaped cutouts in plastic products, offering functionality and aesthetic appeal. The hole punch function allows for the creation of regular holes in different sizes, enabling ventilation or attachment points as needed. Additionally, the t-shirt punch capability enables the machine to create specific cuts or shapes typically used for hanging t-shirts or garments.

By incorporating the D-punch, hole punch, and t-shirt punch functionalities, the Offline Punches Machine expands the creative possibilities and customization options for plastic products. It empowers manufacturers to produce unique and tailored plastic items with enhanced functionality, design, and branding opportunities.

-

Static Eliminators

Static eliminators are crucial in plastic converting machine testing. These devices neutralize static electricity, preventing issues like material sticking, misalignment, and electrostatic discharge. By effectively eliminating static charges, they ensure smooth and efficient operation during the testing process of plastic converting machines.

-

Safety Chuck

The Safety Chuck is an integral component utilized in plastic converting machine testing. It provides a secure and reliable gripping mechanism for holding and rotating the rolls of material, ensuring stable and safe operation during unwinding and rewinding processes.

-

Conveyor Belts

Conveyor belts are integral in plastic converting machine testing. These belts facilitate the smooth and continuous movement of materials or products during the testing process. They ensure efficient transfer, precise positioning, and reliable handling, enabling thorough assessment of the machine’s functionality and performance.

-

Free Falling Dart Impact Tester (For Film)

This Dart Impact Tester is for different plastic films, sheets, Decorative laminates, corrugated roofing sheets etc. with range of Darts & selectable facility of height of fall with low efforts. Its also offer two different Electromagnetic system for light & heavy Dart respectively which would help in selection of dart with smallest possible dart to heaviest one. Tester is equipted with high tech vaccum pump with gauge and clamping system to clamp the film tightly and digital counter for counting no. of test.

-

Ball Shaft

The Ball Shaft is a key component utilized in slitting machines. It provides smooth rotation and stability for various machine functions, including serving as a quick lock mechanism for securely holding and releasing paper cores during the converting process.

-

Chiller

A chiller is a refrigeration device used in plastic machinery. It removes heat from industrial equipment, such as extruders or molds, by circulating chilled water or refrigerant. Chillers maintain precise temperature control, ensuring optimal performance and quality.

-

Edge Guide (Electronics System & Hydraulic System)

The Edge Guide is a critical feature utilized in plastic converting machines for maintaining precise alignment and positioning of plastic materials during the conversion process. The machine employs two types of edge guide systems: an electronic system and a hydraulic system.

The electronic edge guide utilizes a DC motor with a controlling display to automatically adjust and maintain the desired alignment of the plastic material. This system constantly monitors and adjusts the position of the material to ensure accurate processing and minimize waste. It provides real-time feedback and control, allowing for precise and consistent results.

On the other hand, the hydraulic edge guide employs a hydraulic cylinder mechanism to adjust and control the position of the plastic material. This system utilizes hydraulic pressure to move the edge guide mechanism, ensuring precise alignment and tension control. It provides reliable and robust performance in maintaining the alignment of wide plastic materials.

Both the electronic and hydraulic edge guide systems play a crucial role in the plastic converting machine by enabling accurate positioning and alignment of the plastic material. They help achieve consistent and high-quality output by minimizing material waste, reducing errors, and ensuring efficient production processes.

Vaccum Pump

A vacuum pump is an essential tool used in plastic converting machine testing. It creates a vacuum or negative pressure to remove air or gases from a system. In testing, vacuum pumps aid in achieving proper material adhesion, eliminating bubbles, and ensuring the desired quality of plastic products.

Blowers

Blowers are mechanical devices used in various industrial applications, including plastic converting. They generate a high-velocity airflow for processes such as drying, cooling, or exhausting. By providing directed air movement, blowers aid in efficient material handling and help maintain optimal conditions during plastic converting operations.

Cooling Towers

Cooling towers are crucial components of industrial processes, including plastic converting. They remove excess heat from equipment and machinery by circulating and cooling water. By dissipating heat, cooling towers ensure optimal operation, prevent overheating, and maintain efficient performance in plastic converting operations.

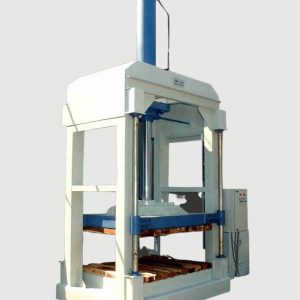

Bale Press Machine

A bale press machine is a specialized equipment used in plastic converting processes. It compresses plastic materials into compact bales for easy storage, transportation, and recycling. It maximizes efficiency, minimizes space requirements, and enhances the overall management of plastic waste in the converting industry.

Conveyor Systems

Conveyor systems are integral to plastic converting machine testing, providing efficient material handling. They consist of belts or rollers that move plastic materials or products along a designated path, facilitating continuous testing processes. Conveyor systems ensure smooth flow, accurate positioning, and seamless integration of plastic components during testing operations.

Power Distribution Panel

A power distribution panel is an electrical enclosure that serves as a central hub for distributing electricity to various devices and equipment in a facility or industrial setting. It safely divides and controls power supply, ensuring efficient and reliable distribution throughout the system.