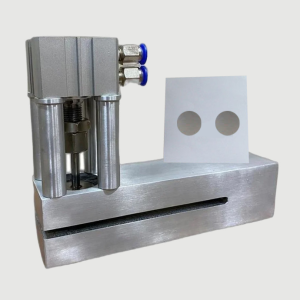

Twin Sealer

The Twin Sealer is employed in plastic converting machinery for the purpose of achieving thicker and stronger seals in bags, particularly those with widths of 5mm, 10mm, and similar dimensions. This specialized sealer ensures enhanced sealing performance, allowing for reliable and durable closures in heavy-duty or thicker plastic bags.

SKU:

VCMP0016

Category: Converting Machine

Related Products

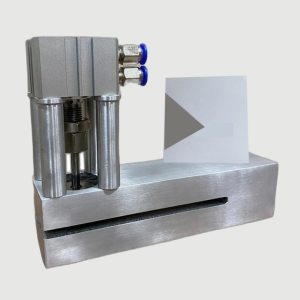

V Notch

The “V-notch” is commonly used in plastic converting machines to facilitate precise and consistent bag tearing. The machine incorporates the V-notch mechanism, which creates a uniform cut or score along the bag’s edge. This enables easy and accurate tearing during the conversion process, ensuring smooth and efficient production of plastic bags.

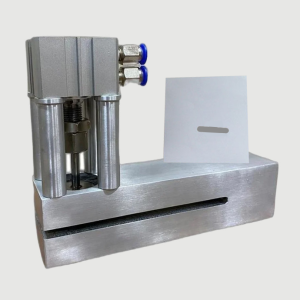

D Cut

The “D-cut” is widely used in plastic converting machines due to its effectiveness in creating secure and reliable handles on plastic bags. By incorporating the D-cut mechanism, the machine can accurately and efficiently cut out the distinctive D-shaped openings in bags, providing convenient and sturdy handles for easy carrying and transportation of various goods. This feature enhances the usability and functionality of the plastic bags produced by the machine.

Header Sealer

The “Header Sealer” is utilized in plastic converting machines for sealing header cards or headers onto plastic bags or packaging. It ensures secure attachment, providing a professional and presentable display and allowing for convenient hanging or presentation of the packaged products.

Round Cut Punch

The “Round Cut Punch” finds its purpose in plastic converting machines for creating circular or round-shaped cutouts in plastic materials. These round cut punches are commonly used for applications such as creating openings for bottle caps, lids, or circular windows in plastic products. The round cut punch ensures precise and uniform cuts, contributing to the functionality, design, and visual appeal of the plastic products manufactured by the machine.

Offline Punch Machine

The Offline Punches Machine in a plastic converting machine is a versatile tool that accommodates various punching operations, including the D-punch, hole punch, and t-shirt punch. It enables manufacturers to add custom shapes, holes, and unique designs to plastic materials during secondary conversion processes.

With the D-punch feature, the machine can create precise D-shaped cutouts in plastic products, offering functionality and aesthetic appeal. The hole punch function allows for the creation of regular holes in different sizes, enabling ventilation or attachment points as needed. Additionally, the t-shirt punch capability enables the machine to create specific cuts or shapes typically used for hanging t-shirts or garments.

By incorporating the D-punch, hole punch, and t-shirt punch functionalities, the Offline Punches Machine expands the creative possibilities and customization options for plastic products. It empowers manufacturers to produce unique and tailored plastic items with enhanced functionality, design, and branding opportunities.

Star Punch

The “Star Punch” is employed in plastic converting machines to create star-shaped cutouts in plastic materials. This feature is commonly used for decorative purposes, adding an appealing and distinctive design element to plastic products. The Star Punch ensures precise and uniform cuts, enhancing the aesthetic value and visual appeal of the final plastic products manufactured by the machine. It is particularly useful in industries where decorative or creative designs are desired, such as crafts, party supplies, and promotional items.

Compressor

Compressor  Continous Band Sealer

Continous Band Sealer  Chiller

Chiller  Conveyor Systems

Conveyor Systems  Strech Wrapping Machine

Strech Wrapping Machine  Cooling Towers

Cooling Towers