-

Empty cart

No products in the cart.

Return to Shop

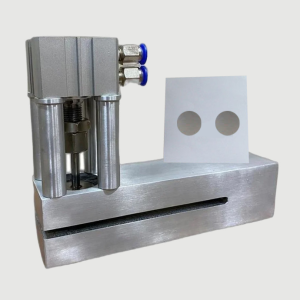

Pin Perforation Roller

The Pin Perforation Roller is essential in plastic converting machines to create precise and uniform perforations on plastic materials. It enables a controlled ventilation or perforated patterns, enhancing the functionality and versatility of plastic bags, packaging or other plastic products.

SKU:

VCMP0019

Category: Converting Machine

Related Products

Retrofitting with Servo Kits

Retrofitting with Servo Kits in plastic converting machines refers to the process of upgrading or modernizing the machine’s existing microcontroller system by replacing it with a new high-speed controller PLC system integrated with servo technology.

The retrofitting process involves removing the outdated microcontroller system and installing a new PLC (Programmable Logic Controller) system that offers improved functionality, performance, and control. The new PLC system is equipped with servo technology, which utilizes high-precision servo motors to provide accurate and precise control over various machine movements, such as cutting, sealing, or feeding.

By retrofitting the machine with servo kits and a new high-speed controller PLC system, manufacturers can significantly enhance the machine’s capabilities and productivity. The servo technology enables better synchronization, faster response times, and more precise positioning, resulting in improved accuracy, speed, and efficiency of the plastic converting process.

Additionally, the new PLC system provides advanced features, such as comprehensive programming options, enhanced diagnostics, and user-friendly interfaces. This allows operators to have better control over the machine’s operations and facilitates easier adjustments, troubleshooting, and optimization of the production process.

Overall, retrofitting with servo kits and a new high-speed controller PLC system in plastic converting machines enables manufacturers to upgrade their equipment, unlocking improved performance, accuracy, and efficiency, thereby maximizing productivity and achieving higher quality output.

Film folding device

The film folding device is utilized in plastic converting machines to precisely fold plastic films, sheets, or materials during the conversion process. It ensures accurate and uniform folding, enabling the creation of various products such as bags, packaging materials, or other folded plastic items with consistent and desired dimensions. The size ranges from 1200mm to 1600mm in width, into tube forms. With a speed range of 30mtr/min to 60mtr/min, it ensures efficient and precise folding of plastic materials. The stand-alone folder streamlines the folding process, allowing for consistent and neatly folded plastic bags and pouches at high production speeds. We have our own special design Folding System for accurate folding without any creasing.

Ultrasonics

Ultrasonics is employed in plastic converting machines for various applications, including squeezing and knurling. Ultrasonic technology utilizes high-frequency vibrations to generate heat and pressure, allowing for effective bonding, cutting, or sealing of plastic materials.

In the context of squeezing applications, ultrasonics can be utilized to join or seal plastic components together. The high-frequency vibrations create localized heat at the contact points, causing the plastic to melt and fuse, resulting in a strong and secure bond. This technique is commonly used in applications such as bag sealing, creating airtight closures, or bonding plastic parts together.

Furthermore, the knurling application of ultrasonics involves creating textured or patterned surfaces on plastic materials. The high-frequency vibrations, when applied to the desired area, can imprint or emboss patterns onto the plastic surface, enhancing grip, aesthetics, or functionality. Knurling is often employed in applications such as improving the grip of handles, creating decorative designs, or providing anti-slip surfaces.

By incorporating ultrasonics in the plastic converting machine, manufacturers can achieve precise and efficient squeezing and knurling processes. The technology offers fast and reliable bonding, sealing, or surface modification of plastic materials, contributing to the overall quality, functionality, and appearance of the final plastic products.

Star Punch

The “Star Punch” is employed in plastic converting machines to create star-shaped cutouts in plastic materials. This feature is commonly used for decorative purposes, adding an appealing and distinctive design element to plastic products. The Star Punch ensures precise and uniform cuts, enhancing the aesthetic value and visual appeal of the final plastic products manufactured by the machine. It is particularly useful in industries where decorative or creative designs are desired, such as crafts, party supplies, and promotional items.

Twin Sealer

The Twin Sealer is employed in plastic converting machinery for the purpose of achieving thicker and stronger seals in bags, particularly those with widths of 5mm, 10mm, and similar dimensions. This specialized sealer ensures enhanced sealing performance, allowing for reliable and durable closures in heavy-duty or thicker plastic bags.

Unwinder Stand with Edge Guide System

The Unwinder stand with edge guide system serves a crucial purpose in plastic converting machines for handling and aligning plastic materials during the conversion process. This component is specifically designed to unwind plastic rolls of varying widths, ranging from 600mm to 1500mm, while ensuring proper edge alignment.

The unwinder stand incorporates an edge guide system that can be either electronic or hydraulic, depending on the specific machine configuration. The electronic edge guide utilizes advanced technology, such as sensors and a controlling display, to automatically adjust and maintain the alignment of the plastic material as it unwinds. This ensures precise and consistent positioning, minimizing waste and ensuring smooth processing.

Alternatively, the hydraulic edge guide system employs hydraulic cylinders to adjust and control the alignment of the plastic material. By applying hydraulic pressure, the system ensures accurate edge alignment and tension control, guaranteeing the stability and uniformity of the material during the unwinding process.

The integration of the unwinder stand with an edge guide system in plastic converting machines enables efficient handling and alignment of plastic materials of different widths. This feature plays a crucial role in maintaining proper tension, alignment, and control of the plastic material, ultimately contributing to high-quality output, reduced waste, and improved production efficiency.