-

Empty cart

No products in the cart.

Return to Shop

Blown Film Plant

HomeBlown Film Plant

Filters

Showing all 19 results

See

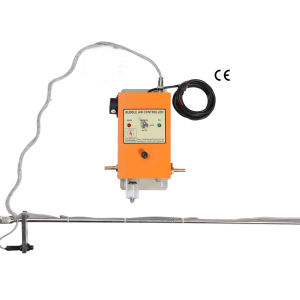

Air Bubble Controller

The Air Bubble Controller is a vital component used in extrusion machines. It facilitates gauge control in the extruder unit for monolayer production, ensuring precise and consistent bubble size, thereby enhancing the quality of the final plastic film.

Air Rings

Air Rings are components used in extrusion machines to enhance output in both monolayer and multilayer production. They provide controlled and uniform air flow to cool and shape the extruded plastic, resulting in improved product quality, increased production speed, and higher overall output.

Air Shafts

Air Shafts are essential components in plastic converting machine testing. They provide a reliable and efficient method for securely holding and supporting rolls of plastic materials during unwinding and rewinding operations, ensuring smooth and controlled material handling for accurate and consistent converting results.

Banana Roller

The Banana Roller is a valuable tool in plastic converting machine testing. Its curved shape and smooth surface enable it to guide and support the plastic material, preventing wrinkles, creases, or any surface defects during the converting process, ensuring high-quality output.

Chiller

The Chiller plays a critical role in extrusion machines. It is responsible for cooling the water used in the machine, controlling and maintaining the temperature of the cooling water to prevent overheating and ensure optimal operating conditions for the converting process.

Cooling Tower

The Cooling Tower is a crucial element in extrusion machines. It is part of the cooling water plant, responsible for dissipating heat from the water used in the machine, ensuring optimal temperature control and preventing overheating during the converting operations. It promotes efficient and consistent cooling performance.

Corona Treater

The Corona Treater is a key component in extrusion machines. It operates within a width range of 500mm to 2300mm and utilizes pneumatic operation along with the latest IGBT technology system. It enhances surface tension on plastic films, enabling better adhesion of inks, coatings, and adhesives for improved printability and product quality.

Dies

Recycle Your Trim Waste On Extruder It Self

The Trim Grinder is a tool employed in plastic converting machine testing for recycling trim waste directly on the extruder. It efficiently grinds and processes the trim waste, allowing it to be reintroduced into the extrusion process, minimizing waste and maximizing material utilization.

Edge Guide

The Edge Guide is an essential component employed in plastic blown film machine to ensure proper winding on the unwinder unit. It precisely guides the plastic material, aligning the edges to achieve uniform winding and prevent any misalignment or material wastage during the production process.

Hopper Loader

The Hopper Loader is used in extrusion machines. It enables automatic feeding of granules into the extruder hopper, ensuring a continuous and consistent supply of material for efficient and uninterrupted production in the extrusion process.

Hopper Magnet

The Hopper Magnet is a crucial component in plastic converting machine testing. It is placed in the hopper or feeding system to capture and remove metal contaminants from the plastic materials, ensuring product quality, equipment protection, and preventing potential damage during the converting process.

Hot Dryer

The Hot Dryer is an essential element in extrusion machine. It utilizes heat to efficiently remove moisture from plastic materials, ensuring optimal quality and performance. It is particularly effective in eliminating moisture in granules or pellets used in the converting process.

Knurling Roller

The Knurling Roller is a vital tool used in extrusion machines. It features a patterned surface that facilitates enhanced grip and traction on plastic materials, ensuring efficient feeding and traction control. Additionally, it is employed for online knurling on extruder plants to create surface textures or patterns on plastic products.

Logo Printing Machine

The Logo Printing Machine is utilized in extrusion machines testing for applying single-color logos onto plastic materials. It integrates with the extruder machine, allowing precise and efficient printing, enhancing product branding and aesthetics in the plastic conversion process.

Mechanical Shaft

The Mechanical Shaft is a vital component in plastic converting machine testing. It provides a secure and adjustable connection between the machine and various components like rollers or blades, facilitating smooth and precise movements, ensuring accurate and efficient processing of plastic materials.

Screen Changer

The Screen Changer is a valuable tool in plastic converting machine testing. It effectively filters out impurities and contaminants from the molten plastic, ensuring a clean and high-quality output. It allows for easy and efficient screen replacement to maintain uninterrupted production during the testing process.

Screw And Barrels

Screws are elements in extrusion machines, specifically barrels screws ranging from 35mm to 75mm in diameter. They are designed as bi-metallic or nitrided, ensuring effective and high-performance operation, resulting in better output and the production of high-quality films.

Trim Grinder

The Trim Grinder is a tool employed for recycling trim waste directly on the extruder. It efficiently grinds and processes the trim waste, allowing it to be reintroduced into the extrusion process, minimizing waste and maximizing material utilization.

Winders (Single Station or Double Station)

Winders, whether Single Station or Double Station, are essential in plastic converting machine testing. They facilitate the precise winding of plastic materials into rolls, ensuring proper tension control, alignment, and consistent winding quality, enabling efficient handling and further processing of the converted products.