-

Empty cart

No products in the cart.

Return to Shop

Consumables

HomeConsumables

Filters

Showing all 48 results

See

Cutting Blades

Cutting blades optimized for plastic converting machine testing are engineered to deliver precise and efficient cuts through various types of plastic materials. These blades possess the necessary sharpness, strength, and compatibility to ensure optimal performance during the plastic conversion process.

Surgical Blades

Surgical blades suitable for plastic converting machine testing are specifically designed and manufactured to meet the requirements of the machine. These blades possess the necessary durability, precision, and material compatibility to ensure successful and efficient plastic conversion processes.

Rotary Blades

Rotary blades are essential components in plastic converting machine testing. They consist of sharp, rotating edges that efficiently cut and shape the plastic material, ensuring precise and uniform results. These blades play a vital role in the manufacturing process, ensuring high-quality output.

Perforated Blades

Perforated blades are specifically designed for plastic converting machine testing. With evenly spaced holes along their edges, they efficiently perforate plastic materials, enabling controlled airflow, moisture management, or creating patterns for various applications in the manufacturing process.

Ceramic Band Heater

Ceramic band heaters are indispensable in plastic converting machine testing. These heaters consist of a ceramic insulator and a resistance heating element wrapped around it. Ceramic band heaters offer uniform heating, ensuring optimal temperature control during plastic conversion processes, leading to accurate testing and enhanced productivity.

Mica Heater

Mica heaters find extensive application in plastic converting machine testing. These heaters utilize mica as an insulating material and have embedded heating elements for efficient heat transfer. Mica heaters ensure consistent and controlled heating, facilitating accurate plastic conversion processes and enhancing overall testing efficiency.

Nozzle Heater

Nozzle heaters are vital components in plastic converting machine testing. Designed specifically for heating nozzles, these heaters ensure precise and uniform temperature distribution at the point of plastic injection. With their efficient heat transfer capabilities, nozzle heaters enable accurate testing and consistent plastic flow, leading to optimal production results.

Coil Heater

Coil heaters are extensively applied in plastic converting machine testing. These high-performance heating elements consist of a tightly wound resistance wire encased in a metal sheath. By delivering rapid and uniform heat, coil heaters enable efficient plastic melting and shaping, facilitating accurate testing and enhancing production outcomes.

Perforated Ceramic Heater

In plastic converting machine testing, perforated ceramic heaters play a pivotal role. These specialized heating elements feature a ceramic body with strategically placed perforations for efficient heat transfer. By evenly distributing heat, they enable precise plastic shaping and ensure consistent product quality and production efficiency.

Cartridge Heater

Cartridge heaters are indispensable in plastic converting machine testing. These compact heating elements, often made of stainless steel, provide controlled and uniform heat. Inserted into the machine, cartridge heaters ensure optimal temperature distribution, enabling precise plastic melting and molding processes with enhanced productivity and reliability.

All Type Cables

All types of cables are employed in plastic converting machine testing to establish connections and transmit signals between different components. These cables include power cables, communication cables, and sensor cables, ensuring reliable and efficient communication and operation of the testing equipment.

All Type PLCs

PLCs (Programmable Logic Controllers) of various types are utilized in plastic converting machine testing. These electronic devices control and automate the machine’s operations, including temperature, speed, pressure, and other parameters, ensuring accurate and efficient performance while maintaining quality standards in the plastic conversion process.

All Type Switch Gears

Switch gears are utilized in plastic converting machine testing to control and protect electrical circuits. They enable the operator to safely switch power on/off, regulate voltage levels, and safeguard the machinery from electrical faults, ensuring safe and efficient testing operations in the plastic converting process.

Bearings

High-performance bearings are essential in plastic converting machine testing. These bearings are specifically designed to withstand heavy loads, high speeds, and harsh operating conditions. They undergo rigorous testing to ensure optimal performance, precision, and durability, contributing to the efficient and reliable operation of plastic converting machines.

Change Over Switch

Changeover switches are used in plastic converting machine testing to facilitate easy switching between different power sources or circuits. They allow operators to quickly transition between power supplies, ensuring uninterrupted testing and enabling the machine to adapt to different electrical configurations or requirements.

Coating Roller

Coating rollers are an integral part of plastic converting machine testing. These rollers apply a thin, uniform coating on plastic substrates, ensuring precise testing and consistent results. By facilitating smooth and controlled coating application, they contribute to the quality and efficiency of the plastic conversion process.

Connectors

Connectors are essential components in plastic converting machine testing as they establish electrical and mechanical connections between different parts and components. They enable the seamless integration of sensors, actuators, power supplies, and control systems, ensuring reliable data transmission and efficient operation during testing processes.

Conveyor Belts

Conveyor belts are integral in plastic converting machine testing. These belts facilitate the smooth and continuous movement of materials or products during the testing process. They ensure efficient transfer, precise positioning, and reliable handling, enabling thorough assessment of the machine’s functionality and performance.

Double Side Mounting Tape For Flexo

Double-sided mounting tape for flexo is extensively tested in plastic converting machines. These machines evaluate the tape’s adhesive strength, flexibility, and compatibility with flexographic printing processes. The tape undergoes rigorous testing to ensure optimal performance and reliable adhesion in plastic converting applications.

Drivers AC/DC/ Servo

AC/DC/Servo drivers are integral to plastic converting machine testing. They regulate the power supply to AC, DC, or servo motors, providing precise control over speed, torque, and positioning. These drivers ensure smooth and accurate operation, enabling efficient and reliable testing in the plastic converting process.

Duck Pipes

Duck Pipes are specially designed plastic conduits used for testing purposes in plastic converting machines. These pipes facilitate the flow of molten plastic, allowing technicians to assess the machine’s performance, accuracy, and functionality.

Encoders

Encoders are essential in plastic converting machine testing to accurately measure position, speed, and direction of moving components. They provide precise feedback, enabling precise control and synchronization of various machine movements, ensuring optimal performance and quality in the plastic converting process.

Gears

Gears are indispensable in plastic converting machine testing. These mechanical components enable power transmission, torque conversion, and precise rotational movement within the machinery. Gears ensure accurate speed control, efficient force distribution, and reliable performance evaluation during testing processes.

Mark Sensors

Mark sensors are devices used in plastic converting machine testing to detect and interpret marks or patterns on plastic materials. They enable accurate positioning, alignment, and quality control during the conversion process, ensuring precise cutting, printing, or other operations.

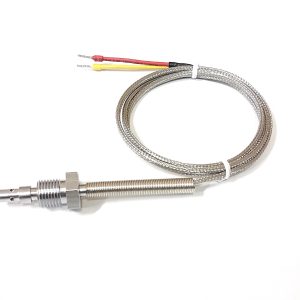

J Type Thermocouples

J type thermocouples are ingeniously employed in plastic converting machine testing. These thermocouples exploit the voltage produced by the junction of different metals to measure temperature. By incorporating J type thermocouples, precise temperature control enhances plastic conversion processes, ensuring impeccable output quality and efficiency.

K Type Thermocouples

K type thermocouples revolutionize temperature measurement. By harnessing the voltage generated from the union of dissimilar metals, these thermocouples accurately monitor and regulate temperature during the conversion process, optimizing plastic production with precision and efficiency.

PT-100 (Platinum Resistance Temperature Detector) Thermocouples

PT-100 (Platinum Resistance Temperature Detector) is commonly used in plastic converting machine testing. It is a temperature sensor that utilizes a platinum element to measure temperature with high accuracy and stability, allowing for precise temperature monitoring and control during the testing process.

RTD (Resistance Temperature Detector) Thermocouples

RTD (Resistance Temperature Detector) is a type of sensor used in plastic converting machine testing to measure temperature accurately. It consists of a wire coil or thin film that changes resistance with temperature variations, providing precise temperature data for monitoring and control purposes during testing.

MCB MCCB ELCB

MCB (Miniature Circuit Breaker), MCCB (Molded Case Circuit Breaker), and ELCB (Earth Leakage Circuit Breaker) are electrical protection devices used in plastic converting machine testing. They automatically detect and interrupt electrical faults, such as overloads, short circuits, or earth leakages, safeguarding the machine and preventing damage or accidents.

Motor AC/DC

AC/DC motors are key components in plastic converting machine testing. AC motors convert electrical energy into rotational motion, while DC motors use direct current. These motors provide power for various machine functions, such as driving conveyor belts, rollers, or other mechanical components during testing operations.

Nichrom Wires

Discover high-quality Nichrome wires for plastic converting machine testing. These durable and heat-resistant wires are designed to withstand demanding conditions, ensuring accurate and efficient testing. Enhance your testing process with reliable Nichrome wires that deliver reliable results every time.

Oil Seals

Oil seals are essential components used in plastic converting machines to prevent leakage of oil and protect the machinery from contaminants. They provide a tight seal between moving parts, ensuring smooth operation and extending the machine’s lifespan.

Packaging Tapes

Packaging tapes undergo rigorous testing in plastic converting machines. These machines evaluate the tapes’ strength, adhesion, and durability, ensuring they meet quality standards. The tapes are subjected to various mechanical and environmental conditions to assess their performance and suitability for packaging applications.

Pid And Digital Temp. Controller

PID (Proportional-Integral-Derivative) and digital temperature controllers are essential in plastic converting machine testing. They precisely regulate and maintain the temperature of heating elements or zones, ensuring optimal process conditions and consistent quality during the plastic converting process.

Pneumatics All Types

Pneumatics, encompassing various types of pneumatic components, play a crucial role in plastic converting machine testing. Utilizing compressed air, they control actuators, valves, and other devices, facilitating precise movement, gripping, and positioning of materials, ensuring efficient and accurate testing in the plastic converting process.

Power Supply

The power supply used in plastic converting machine testing is an electrical device that provides the necessary electrical energy to operate the machine. It ensures a stable and consistent power source, enabling the machine to function efficiently and accurately during testing.

Pulley

Pulleys are crucial components in plastic converting machine testing. Designed with precision, these pulleys ensure smooth and efficient rotation of belts or other mechanical components, allowing accurate evaluation of power transmission, tension control, and overall performance of the machine during testing processes.

Rubber Strips

Rubber strips are suitable for testing in plastic converting machines. These strips offer flexibility, durability, and high friction properties, ensuring accurate performance evaluation and compatibility assessment within the machinery’s operational parameters.

Sensors

Sensors are utilized in plastic converting machine testing to monitor various parameters and ensure proper functioning. They detect factors like temperature, pressure, speed, position, and presence of objects, providing real-time feedback for control and optimization, ensuring reliable and accurate testing results.

Silicon Sleeves

Silicon sleeves are extensively utilized for testing purposes in plastic converting machines. With their heat resistance, excellent insulation properties, and smooth surface, these sleeves provide effective protection, seamless operation, and precise evaluation of the machine’s performance and compatibility.

SSR

Enhance your plastic converting machine testing with top-notch SSRs (Solid State Relays). These reliable electronic switches provide precise control and seamless operation, ensuring optimal performance. Choose high-quality SSRs for accurate and efficient testing of your plastic converting machines.

Static Eliminators

Static eliminators are crucial in plastic converting machine testing. These devices neutralize static electricity, preventing issues like material sticking, misalignment, and electrostatic discharge. By effectively eliminating static charges, they ensure smooth and efficient operation during the testing process of plastic converting machines.

Teflon Cloths

Discover Teflon cloths for plastic converting machine testing. These specialized cloths offer exceptional heat resistance and non-stick properties, ensuring smooth material flow and preventing sticking. Enhance your testing accuracy and efficiency with high-quality Teflon cloths for optimal results.

Timing Belts

Timing belts are essential in plastic converting machine testing. These belts feature toothed surfaces that engage with corresponding pulleys, providing precise synchronization and accurate positioning of machine components. They ensure reliable power transmission, smooth operation, and precise evaluation of the machine’s performance during testing.

Torque Controller

A torque controller is utilized in plastic converting machine testing to ensure precise and consistent torque application. It helps achieve proper assembly, prevent over-tightening or under-tightening, and ensures the desired quality and functionality of plastic components during the testing process.

Transfer Roller

The transfer roller, used in plastic converting machine testing, is a crucial component that facilitates the transfer of materials during the manufacturing process. It ensures smooth and efficient movement of plastic through the machinery, enabling accurate and consistent production.

V Belts

V belts used in plastic converting machine testing. These specially designed belts offer excellent traction, high power transmission capabilities, and resistance to wear and tear. They ensure smooth and efficient operation while assessing the machine’s performance, stability, and reliability during testing.

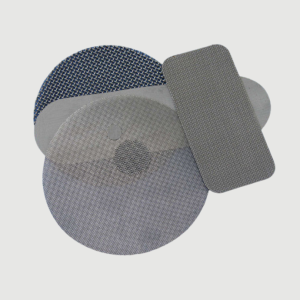

Wire Mesh

Explore durable wire mesh for plastic converting machine testing. This versatile mesh provides excellent support and stability during testing processes, ensuring consistent and accurate results. Enhance your testing efficiency with high-quality wire mesh designed specifically for plastic converting machines.