-

Empty cart

No products in the cart.

Return to Shop

Printing & Lamination

HomePrinting & Lamination

Filters

Showing all 19 results

See

Simple Wall Fix Stroboscope

A simple wall fix stroboscope is a device used in printing and lamination machines, specifically for checking printing corrections. It is mounted on a wall and emits pulsating light, which can be synchronized with the printing process, enabling operators to observe and rectify any printing errors or alignment problems accurately.

Handy Stroboscope

A handy stroboscope is a tool used in printing and lamination machines, particularly for checking printing corrections. It emits short, intense bursts of light, allowing operators to freeze the motion of rotating parts, such as printing cylinders, to identify and correct any printing defects or alignment issues accurately.

Pneumatic Operated Ink Pump

In printing and lamination machines, a pneumatic-operated ink pump proves suitable for facilitating the circulation of ink in the printing tray. This pump employs compressed air to efficiently and accurately deliver ink, ensuring optimal printing performance and consistent ink flow.

AC Motor Operated Ink Pump

In printing and lamination machines, an AC motor-operated ink pump is utilized to facilitate the circulation of ink in the printing tray. This pump ensures a consistent and reliable supply of ink, enabling smooth and high-quality printing operations.

Anilox Roller

An anilox roller is a key component in plastic converting machine testing. It transfers a controlled amount of ink or coating onto the doctor blade, which then applies it to the printing or coating rolls. This ensures consistent and precise ink or coating distribution for optimal print quality.

Ceramic Roller

Ceramic rollers are widely used in plastic converting machine testing. These rollers offer excellent heat resistance, wear resistance, and smooth surface properties. They ensure precise material handling, minimize friction, and provide accurate performance evaluation during testing processes, contributing to overall operational efficiency.

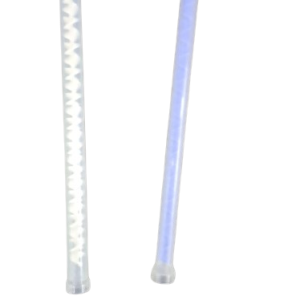

Doctor Blades

Doctor blades are utilized in plastic converting machine testing to control the application of inks or coatings. They act as flexible, precise scraping tools, removing excess material from the printing or coating rolls, ensuring uniform coverage and high-quality results.

Edge Guide

Edge guides are likely employed in plastic converting machine testing. These guides help ensure precise alignment and control of the plastic material as it passes through the machine. They enhance accuracy, minimize material wastage, and assist in evaluating the machine’s performance during testing processes.

Gears

In the testing phase of a plastic converting machine, gears are examined for their functionality and durability. These gears play a crucial role in the machine’s operation, ensuring the efficient conversion of plastic materials into desired products.

Heater Zone

Heater zones are essential components in plastic converting machine testing. These zones consist of heating elements that provide controlled and uniform heat to specific sections of the machine. They enable the testing of temperature-sensitive plastic materials, ensuring proper heating and evaluating the machine’s thermal performance.

Magnetic Roller

Magnetic rollers are highly beneficial in plastic converting machine testing. These rollers incorporate magnetic fields to attract and separate metallic impurities from plastic materials, ensuring purity and quality control. They enhance the testing process by removing contaminants and ensuring optimal material integrity.

Printing Cylinder

Printing cylinders is used in plastic converting machine testing. These cylinders feature engraved or etched patterns that transfer ink onto the plastic material, allowing for precise and consistent printing. They enable accurate evaluation of printing quality and performance during testing processes.

Rubber Roller

A rubber roller is an essential element in plastic converting machine testing. It is responsible for guiding and conveying the plastic material through various stages of the machine. The rubber surface provides friction and stability, ensuring smooth and consistent material movement for accurate processing.

Static Brush

Static brushes are effectively utilized in printing and lamination machines to remove static charges on film. These brushes consist of conductive bristles that neutralize and dissipate static electricity, preventing unwanted adhesion, sticking, or misalignment of the film during the testing process.

Static Electrode And Unit

Static electrodes and units are extensively used in printing and lamination machines to eliminate static charges on film. These devices generate ionized air or apply direct charges to neutralize static electricity, ensuring the film remains static-free during the testing process, preventing issues such as misfeeding or improper winding.

Static Mixer

Static mixers are essential in plastic converting machine testing. These devices efficiently blend and homogenize plastic materials by dividing and recombining them through a series of stationary mixing elements. They ensure consistent material composition and quality control during the testing process.

Teflon Dam

Teflon dams are utilized in plastic converting machine testing. These dams, made of Teflon material, are strategically placed to control the flow and containment of molten plastic within the machine. They provide excellent heat resistance, chemical resistance, and prevent leakage or overflow during testing processes.

Tension Controller

A tension controller is an essential component used in plastic converting machine testing. It regulates and maintains the appropriate tension of the plastic material during the conversion process, ensuring smooth and accurate operations.

Web Camera

In printing and lamination machines, a web camera is employed for the correction of printing registration. The camera captures real-time images of the printing process, allowing for precise alignment and adjustment to ensure accurate registration and high-quality printed output.