-

Empty cart

No products in the cart.

Return to Shop

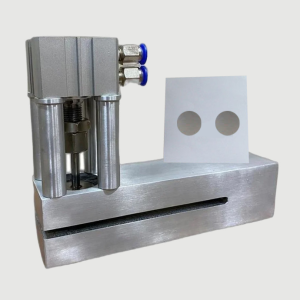

Edge Guide (Electronics System & Hydraulic System)

The Edge Guide is a critical feature utilized in plastic converting machines for maintaining precise alignment and positioning of plastic materials during the conversion process. The machine employs two types of edge guide systems: an electronic system and a hydraulic system.

The electronic edge guide utilizes a DC motor with a controlling display to automatically adjust and maintain the desired alignment of the plastic material. This system constantly monitors and adjusts the position of the material to ensure accurate processing and minimize waste. It provides real-time feedback and control, allowing for precise and consistent results.

On the other hand, the hydraulic edge guide employs a hydraulic cylinder mechanism to adjust and control the position of the plastic material. This system utilizes hydraulic pressure to move the edge guide mechanism, ensuring precise alignment and tension control. It provides reliable and robust performance in maintaining the alignment of wide plastic materials.

Both the electronic and hydraulic edge guide systems play a crucial role in the plastic converting machine by enabling accurate positioning and alignment of the plastic material. They help achieve consistent and high-quality output by minimizing material waste, reducing errors, and ensuring efficient production processes.