-

Empty cart

No products in the cart.

Return to Shop

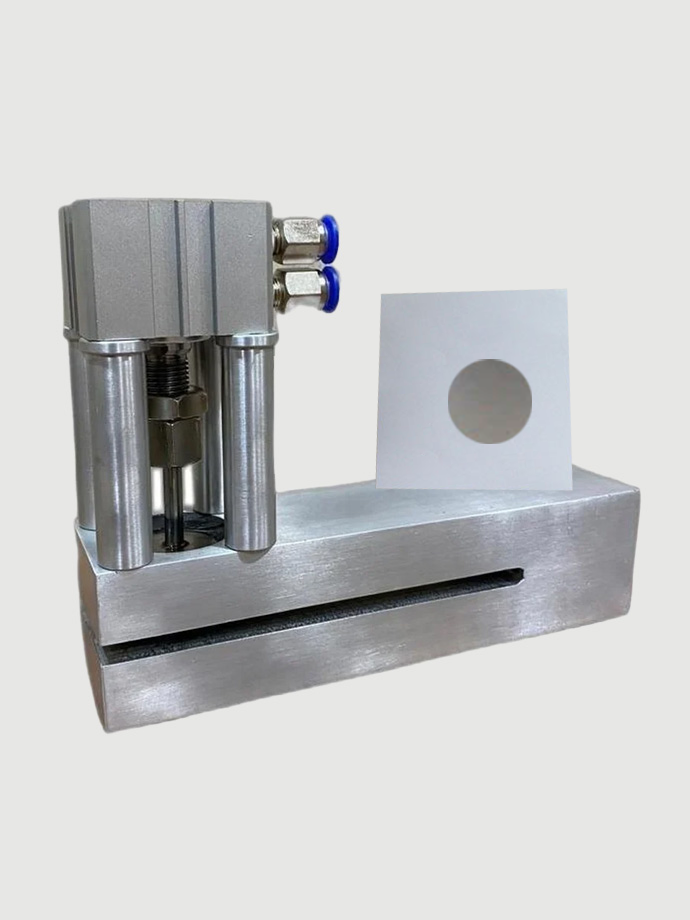

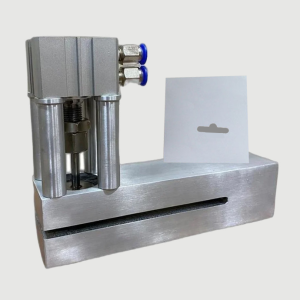

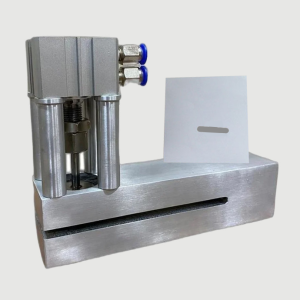

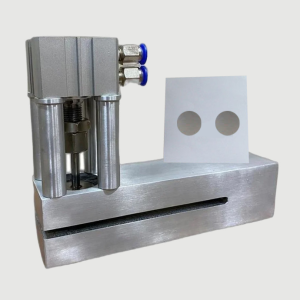

Hole Punch

A versatile tool for creating holes, the hole punch is essential for enhancing air circulation in various applications such as nursery bags and fruit bags. It promotes optimal ventilation, aiding in the growth and preservation of plants and fruits.

Related Products

Header Sealer

The “Header Sealer” is utilized in plastic converting machines for sealing header cards or headers onto plastic bags or packaging. It ensures secure attachment, providing a professional and presentable display and allowing for convenient hanging or presentation of the packaged products.

Twin Sealer

The Twin Sealer is employed in plastic converting machinery for the purpose of achieving thicker and stronger seals in bags, particularly those with widths of 5mm, 10mm, and similar dimensions. This specialized sealer ensures enhanced sealing performance, allowing for reliable and durable closures in heavy-duty or thicker plastic bags.

Conveyor Belts

Conveyor belts are integral in plastic converting machine testing. These belts facilitate the smooth and continuous movement of materials or products during the testing process. They ensure efficient transfer, precise positioning, and reliable handling, enabling thorough assessment of the machine’s functionality and performance.

Stand Alone Folder

Folding Film Sheetform To Tube Form Widht 1200Mm To 1600Mm Speed 30Mtr/Min To 60Mtr/Min

The “Stand alone folder” is a crucial component in plastic converting machines used for folding film sheets, ranging from 1200mm to 1600mm in width, into tube forms. With a speed range of 30mtr/min to 60mtr/min, it ensures efficient and precise folding of plastic materials. This feature contributes to the overall functionality and quality of the plastic products, including bags or packaging materials, produced by the machine. The stand-alone folder streamlines the folding process, allowing for consistent and neatly folded plastic products at high production speeds.

D Cut

The “D-cut” is widely used in plastic converting machines due to its effectiveness in creating secure and reliable handles on plastic bags. By incorporating the D-cut mechanism, the machine can accurately and efficiently cut out the distinctive D-shaped openings in bags, providing convenient and sturdy handles for easy carrying and transportation of various goods. This feature enhances the usability and functionality of the plastic bags produced by the machine.

Wicket Hole Punch

The “Wicket Hole Punch” serves a specific purpose in plastic converting machines by creating holes or slots in plastic materials that are used for wicketing. Wicketing refers to the process of attaching multiple bags together on a wicket, allowing for easy handling and packaging. The Wicket Hole Punch ensures precise and consistent holes or slots, enabling smooth wicketing of plastic bags during the manufacturing process. This feature enhances the efficiency and convenience of packaging operations in industries such as food, retail, and manufacturing.