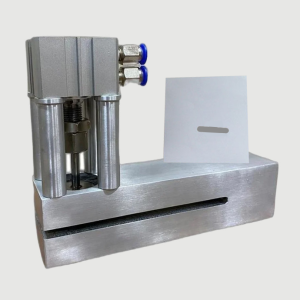

The Offline Punches Machine in a plastic converting machine is a versatile tool that accommodates various punching operations, including the D-punch, hole punch, and t-shirt punch. It enables manufacturers to add custom shapes, holes, and unique designs to plastic materials during secondary conversion processes.

With the D-punch feature, the machine can create precise D-shaped cutouts in plastic products, offering functionality and aesthetic appeal. The hole punch function allows for the creation of regular holes in different sizes, enabling ventilation or attachment points as needed. Additionally, the t-shirt punch capability enables the machine to create specific cuts or shapes typically used for hanging t-shirts or garments.

By incorporating the D-punch, hole punch, and t-shirt punch functionalities, the Offline Punches Machine expands the creative possibilities and customization options for plastic products. It empowers manufacturers to produce unique and tailored plastic items with enhanced functionality, design, and branding opportunities.

Pneumatic Operated Ink Pump

Pneumatic Operated Ink Pump  Rubber Roller

Rubber Roller  Ceramic Roller

Ceramic Roller