₹0.00

Retrofitting with Servo Kits

Retrofitting with Servo Kits in plastic converting machines refers to the process of upgrading or modernizing the machine’s existing microcontroller system by replacing it with a new high-speed controller PLC system integrated with servo technology.

The retrofitting process involves removing the outdated microcontroller system and installing a new PLC (Programmable Logic Controller) system that offers improved functionality, performance, and control. The new PLC system is equipped with servo technology, which utilizes high-precision servo motors to provide accurate and precise control over various machine movements, such as cutting, sealing, or feeding.

By retrofitting the machine with servo kits and a new high-speed controller PLC system, manufacturers can significantly enhance the machine’s capabilities and productivity. The servo technology enables better synchronization, faster response times, and more precise positioning, resulting in improved accuracy, speed, and efficiency of the plastic converting process.

Additionally, the new PLC system provides advanced features, such as comprehensive programming options, enhanced diagnostics, and user-friendly interfaces. This allows operators to have better control over the machine’s operations and facilitates easier adjustments, troubleshooting, and optimization of the production process.

Overall, retrofitting with servo kits and a new high-speed controller PLC system in plastic converting machines enables manufacturers to upgrade their equipment, unlocking improved performance, accuracy, and efficiency, thereby maximizing productivity and achieving higher quality output.

Ceramic Band Heater

Ceramic Band Heater  Mica Heater

Mica Heater  Nozzle Heater

Nozzle Heater  Rubber Strips

Rubber Strips  Static Eliminators

Static Eliminators  RTD (Resistance Temperature Detector) Thermocouples

RTD (Resistance Temperature Detector) Thermocouples  Coil Heater

Coil Heater  Bearings

Bearings  Timing Belts

Timing Belts  Conveyor Belts

Conveyor Belts  Surgical Blades

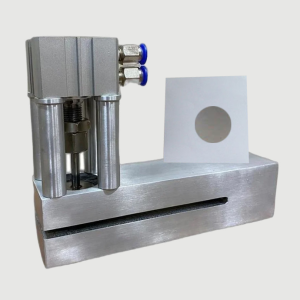

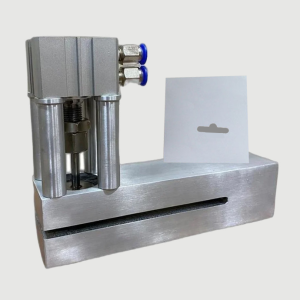

Surgical Blades  Butterfly Punch

Butterfly Punch