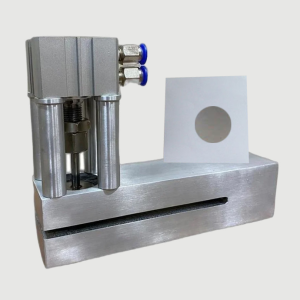

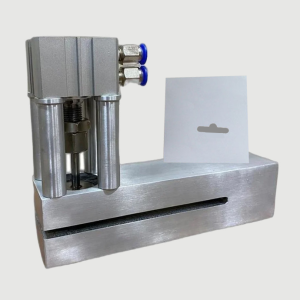

Round Cut Punch

The “Round Cut Punch” finds its purpose in plastic converting machines for creating circular or round-shaped cutouts in plastic materials. These round cut punches are commonly used for applications such as creating openings for bottle caps, lids, or circular windows in plastic products. The round cut punch ensures precise and uniform cuts, contributing to the functionality, design, and visual appeal of the plastic products manufactured by the machine.