-

Empty cart

No products in the cart.

Return to Shop

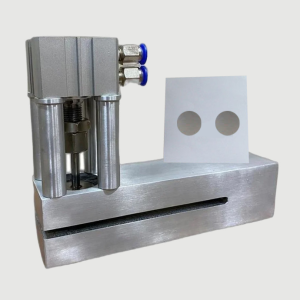

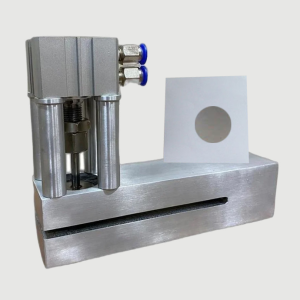

Star Punch

The “Star Punch” is employed in plastic converting machines to create star-shaped cutouts in plastic materials. This feature is commonly used for decorative purposes, adding an appealing and distinctive design element to plastic products. The Star Punch ensures precise and uniform cuts, enhancing the aesthetic value and visual appeal of the final plastic products manufactured by the machine. It is particularly useful in industries where decorative or creative designs are desired, such as crafts, party supplies, and promotional items.