-

Empty cart

No products in the cart.

Return to Shop

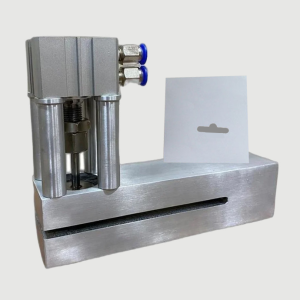

Vacuum Leakage Tester (200 x 300)

Vishva’s Leakage Tester stands as a crucial asset for industries prioritizing product integrity and safety. Its role is to guarantee that products adhere to the most stringent quality standards, aiding manufacturers in upholding customer trust and preserving brand reputation.

SKU:

VC0058

Category: Lab Instruments

Related Products

Heat Seal Tester

Laboratory Heat Sealer

The Laboratory Heat Sealer serves as essential equipment for preparing laboratory samples of heat-sealed pouches/sachets.

The equipment is referred to as Heat Sealing Machine, Heat Sealer, Heat Sealing Tester, Gradient Heat Sealer, Digital Heat Sealing Machine, Heat Sealing Testing Equipment, etc.

Moisture Analyzer

Maintaining low moisture content is crucial for plastic resins, as manufacturers of plastic products understand that high moisture levels in plastic resins can lead to substandard final products.

Vishva’s Moisture Analyzer utilizes a drying process to extract and measure moisture. By integrating a precision balance and a heater, it facilitates the accurate determination of even the slightest moisture content in a reliable and efficient manner within minutes. This enhances your processes and elevates the quality of your products.

Vishva’s SMA-120 plastic moisture analyzer serves as an ideal tool for determining moisture content in plastic pellets, resins, and various polymers like polyamides. Its user-friendly operation and robust design enable swift and chemical-free moisture analysis directly on the production floor, contributing to efficient quality control processes.

Opacity and Transparency Tester

The Opacity Tester is utilized to assess the optical characteristics of plastics, encompassing color, clarity, overall appearance, and directly measurable properties.

It provides a direct percentage reading of light passing through the specimen, with a precise least count.

The design is crafted to ensure a maintenance-free, long life for the apparatus, and it features dust-free specimen chambers.

The equipment is recognized by various names such as Opacity Tester, Opacimeter Tester, Opacity Tester for Plastic, Digital Opacity Tester, Opacity Testing Equipments, Plastic Opacity Testing Equipments, etc.

Air Circulating Hot Air Oven

Crafted for extended usage, our robust designs at Vishva are remarkably durable and user-friendly. The quality insulation not only guarantees safety but also prevents heat loss. The air circulation feature ensures an even distribution of heat, preventing temperature fluctuations and maintaining a consistently uniform temperature throughout the heated area. The incorporation of high-quality digital controllers ensures precise temperature control and accuracy, contributing to consistent and reliable outcomes.

Tailored for the testing of thermoplastic pipes and fittings, Hot Air Ovens from Vishva are available in a range of sizes, allowing customization to meet user requirements.

Color Matching Cabinet

Metamerism is a phenomenon in which test samples appear to match under one light source but appear different when viewed under another light source. Color Matching Cabinets are devices designed to confirm the color consistency of various products.

Vishva’s Color Matching Cabinet offers a standardized environment for the evaluation and visual assessment of color. It is strongly recommended for laboratories to assess the quality and color consistency of paint, plating, textiles, paper, and more.