-

Empty cart

No products in the cart.

Return to Shop

Shop

HomeShop

Filters

Showing 1–60 of 152 results

See

Air Circulating Hot Air Oven

Crafted for extended usage, our robust designs at Vishva are remarkably durable and user-friendly. The quality insulation not only guarantees safety but also prevents heat loss. The air circulation feature ensures an even distribution of heat, preventing temperature fluctuations and maintaining a consistently uniform temperature throughout the heated area. The incorporation of high-quality digital controllers ensures precise temperature control and accuracy, contributing to consistent and reliable outcomes.

Tailored for the testing of thermoplastic pipes and fittings, Hot Air Ovens from Vishva are available in a range of sizes, allowing customization to meet user requirements.

Balloon Burst Tester

The Balloon Burst Test is a specific examination employed to ascertain the burst strength of plastic, polymer films, and packaging materials. This test is crucial in ensuring the resilience of these materials against pressures encountered during storage, transportation, and regular usage.

Certain applications, such as medical devices or packaging for hazardous materials, demand strict adherence to burst strength standards to guarantee safety.

Vishva offers exceptionally accurate measurements of burst strength, ensuring that your materials align with the required standards and specifications. This process assures the robustness and dependability of materials in diverse applications, enabling you to uphold product integrity, comply with safety and regulatory standards, and optimize material selection according to your specific requirements.

Co-Efficient of Friction Tester (COF)

COF tester is designed to determine the co-efficient of friction of plastic films, sheets, laminates, pipes and paper etc. Testing Standards are ASTM D-1894, BS 2782 and other equivalent.

Color Matching Cabinet

Metamerism is a phenomenon in which test samples appear to match under one light source but appear different when viewed under another light source. Color Matching Cabinets are devices designed to confirm the color consistency of various products.

Vishva’s Color Matching Cabinet offers a standardized environment for the evaluation and visual assessment of color. It is strongly recommended for laboratories to assess the quality and color consistency of paint, plating, textiles, paper, and more.

Dart Impact Tester (Pneumatic Holding)

The impact properties of polymeric materials directly influence the overall toughness of the material.

Toughness is defined as the polymer’s ability to absorb applied energy. Plastic films are commonly utilized for packaging purposes and are subjected to wear and tear. Therefore, the strength of impact resistance is crucial for assessing the quality and determining the impact load the film can withstand.

This method involves evaluating the energy that causes plastic film to fail under specific conditions of the impact of a freely falling dart.

Machine is Designed According to ASTM

Pneumatically Operated Clamps have been used to hold Film.

Electromagnetic Centering device provided to Ensure reproducible drop.

Dart drop mechanism is providing to dart drop at different Drop height.

Digital Dead Weight Type Thickness Gauge

Vishva’s Dead Weight Type Thickness Gauge is a precision tool employed for accurately measuring the thickness of materials. Its operation relies on applying a known force to a probe or anvil and then measuring the deformation or deflection of the material being tested.

Free Falling Dart Impact Tester (For Film)

This Dart Impact Tester is for different plastic films, sheets, Decorative laminates, corrugated roofing sheets etc. with range of Darts & selectable facility of height of fall with low efforts. Its also offer two different Electromagnetic system for light & heavy Dart respectively which would help in selection of dart with smallest possible dart to heaviest one. Tester is equipted with high tech vaccum pump with gauge and clamping system to clamp the film tightly and digital counter for counting no. of test.

GSM Testing Machine

Introducing our GSM Testing Machine for Plastic Converting Machineries ? a cutting-edge instrument for accurately determining the weight of various packaging materials like knitting fabrics, paper cardboards, and non-woven fabrics. This advanced machine ensures precise GSM tests, providing crucial insights into material traits before customer delivery. Trust our instrument for reliable measurements, maintaining consistent quality in plastic converting processes.

Heat Seal Tester

Laboratory Heat Sealer

The Laboratory Heat Sealer serves as essential equipment for preparing laboratory samples of heat-sealed pouches/sachets.

The equipment is referred to as Heat Sealing Machine, Heat Sealer, Heat Sealing Tester, Gradient Heat Sealer, Digital Heat Sealing Machine, Heat Sealing Testing Equipment, etc.

Moisture Analyzer

Maintaining low moisture content is crucial for plastic resins, as manufacturers of plastic products understand that high moisture levels in plastic resins can lead to substandard final products.

Vishva’s Moisture Analyzer utilizes a drying process to extract and measure moisture. By integrating a precision balance and a heater, it facilitates the accurate determination of even the slightest moisture content in a reliable and efficient manner within minutes. This enhances your processes and elevates the quality of your products.

Vishva’s SMA-120 plastic moisture analyzer serves as an ideal tool for determining moisture content in plastic pellets, resins, and various polymers like polyamides. Its user-friendly operation and robust design enable swift and chemical-free moisture analysis directly on the production floor, contributing to efficient quality control processes.

Opacity and Transparency Tester

The Opacity Tester is utilized to assess the optical characteristics of plastics, encompassing color, clarity, overall appearance, and directly measurable properties.

It provides a direct percentage reading of light passing through the specimen, with a precise least count.

The design is crafted to ensure a maintenance-free, long life for the apparatus, and it features dust-free specimen chambers.

The equipment is recognized by various names such as Opacity Tester, Opacimeter Tester, Opacity Tester for Plastic, Digital Opacity Tester, Opacity Testing Equipments, Plastic Opacity Testing Equipments, etc.

Peel Bond Tester

Peel and Bond Testers play a crucial role in evaluating the adhesion and bond strength of diverse materials and adhesive products. These instruments measure the force needed to separate two bonded surfaces, offering valuable insights into the quality of the bond.

Vishva’s Peel and Bond Tester stands out as a versatile and dependable tool in industries where the quality of adhesive bonds is critical. It is employed to gauge the adhesive strength or peel resistance of adhesive bonds, laminated materials, and coatings. The machine applies a controlled force to peel a part or separate the bonded materials.

This tool empowers manufacturers to evaluate and improve the bond strength of their products, ensuring they meet customer expectations and exhibit reliable performance across various applications.

Tear Tester

This procedure is utilized for measuring the tear strength of thermoplastic films or non-rigid sheets. Through this test method, we determine the average force required to propagate tearing through a specified length of plastic film or non-rigid sheeting.

This test method is valuable for ranking the relative tearing resistance of various plastic films and sheets of comparable thickness.

Unique Selling Proposition (USP)

It consists of stationary and movable clamps, a stopper for holding the pendulum in a raised position and releasing it instantaneously, and an indicating device for taking the reading of pendulum swings when released. Additionally, a template die or shear-type cutter is included for cutting specimens.

The equipment is recognized by various names such as Tear Strength Tester, Tensile & Tear Strength Test Equipments, Tear Resistance Tester, Digital Tear Strength Tester, Tear Strength Testing Machine, Plastic Film & Sheet Tear Strength Test Equipment, Plastic Lab Sample Tear Strength Tester, etc.

Vacuum Leakage Tester (200 x 300)

Vishva’s Leakage Tester stands as a crucial asset for industries prioritizing product integrity and safety. Its role is to guarantee that products adhere to the most stringent quality standards, aiding manufacturers in upholding customer trust and preserving brand reputation.

Lug Type Airshaft

The Lug Type Airshaft for slitter machines is a cutting-edge solution for seamless and efficient slitting operations. Its robust lug design ensures secure gripping and precise control, guaranteeing reliable tension management during the slitting process, thereby enhancing overall productivity and performance. Available in following materials:- Steel, Rubber, Plastic, Pipe-Steel & Aluminium.

Multi Bladder Type Airshaft

The Multi Bladder Type Airshaft for slitter machines boasts cutting-edge technology, ensuring precise control and optimal tension during slitting operations. With multiple bladders for enhanced stability, this innovative airshaft maximizes efficiency and delivers unparalleled performance in the slitting process. Available in following materials:- Steel, Rubber, Plastic, Pipe-Steel & Aluminium.

Quick Lock (Ball Lock)

Sizes:- 3’6″, 3’12”, 6’6″, 6’12”

The Quick Lock (Ball Lock) is used in plastic converting machine testing. This mechanism, consisting of six locking balls, is employed to secure and hold plastic materials in place during the conversion process, ensuring stability and precise alignment for efficient and accurate transformations.

Simple Wall Fix Stroboscope

A simple wall fix stroboscope is a device used in printing and lamination machines, specifically for checking printing corrections. It is mounted on a wall and emits pulsating light, which can be synchronized with the printing process, enabling operators to observe and rectify any printing errors or alignment problems accurately.

Handy Stroboscope

A handy stroboscope is a tool used in printing and lamination machines, particularly for checking printing corrections. It emits short, intense bursts of light, allowing operators to freeze the motion of rotating parts, such as printing cylinders, to identify and correct any printing defects or alignment issues accurately.

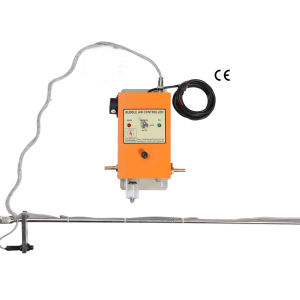

Pneumatic Operated Ink Pump

In printing and lamination machines, a pneumatic-operated ink pump proves suitable for facilitating the circulation of ink in the printing tray. This pump employs compressed air to efficiently and accurately deliver ink, ensuring optimal printing performance and consistent ink flow.

AC Motor Operated Ink Pump

In printing and lamination machines, an AC motor-operated ink pump is utilized to facilitate the circulation of ink in the printing tray. This pump ensures a consistent and reliable supply of ink, enabling smooth and high-quality printing operations.

Air Bubble Controller

The Air Bubble Controller is a vital component used in extrusion machines. It facilitates gauge control in the extruder unit for monolayer production, ensuring precise and consistent bubble size, thereby enhancing the quality of the final plastic film.

Air Rings

Air Rings are components used in extrusion machines to enhance output in both monolayer and multilayer production. They provide controlled and uniform air flow to cool and shape the extruded plastic, resulting in improved product quality, increased production speed, and higher overall output.

Air Shafts

Air Shafts are essential components in plastic converting machine testing. They provide a reliable and efficient method for securely holding and supporting rolls of plastic materials during unwinding and rewinding operations, ensuring smooth and controlled material handling for accurate and consistent converting results.

Cutting Blades

Cutting blades optimized for plastic converting machine testing are engineered to deliver precise and efficient cuts through various types of plastic materials. These blades possess the necessary sharpness, strength, and compatibility to ensure optimal performance during the plastic conversion process.

Surgical Blades

Surgical blades suitable for plastic converting machine testing are specifically designed and manufactured to meet the requirements of the machine. These blades possess the necessary durability, precision, and material compatibility to ensure successful and efficient plastic conversion processes.

Rotary Blades

Rotary blades are essential components in plastic converting machine testing. They consist of sharp, rotating edges that efficiently cut and shape the plastic material, ensuring precise and uniform results. These blades play a vital role in the manufacturing process, ensuring high-quality output.

Perforated Blades

Perforated blades are specifically designed for plastic converting machine testing. With evenly spaced holes along their edges, they efficiently perforate plastic materials, enabling controlled airflow, moisture management, or creating patterns for various applications in the manufacturing process.

Ceramic Band Heater

Ceramic band heaters are indispensable in plastic converting machine testing. These heaters consist of a ceramic insulator and a resistance heating element wrapped around it. Ceramic band heaters offer uniform heating, ensuring optimal temperature control during plastic conversion processes, leading to accurate testing and enhanced productivity.

Mica Heater

Mica heaters find extensive application in plastic converting machine testing. These heaters utilize mica as an insulating material and have embedded heating elements for efficient heat transfer. Mica heaters ensure consistent and controlled heating, facilitating accurate plastic conversion processes and enhancing overall testing efficiency.

Nozzle Heater

Nozzle heaters are vital components in plastic converting machine testing. Designed specifically for heating nozzles, these heaters ensure precise and uniform temperature distribution at the point of plastic injection. With their efficient heat transfer capabilities, nozzle heaters enable accurate testing and consistent plastic flow, leading to optimal production results.

Coil Heater

Coil heaters are extensively applied in plastic converting machine testing. These high-performance heating elements consist of a tightly wound resistance wire encased in a metal sheath. By delivering rapid and uniform heat, coil heaters enable efficient plastic melting and shaping, facilitating accurate testing and enhancing production outcomes.

Perforated Ceramic Heater

In plastic converting machine testing, perforated ceramic heaters play a pivotal role. These specialized heating elements feature a ceramic body with strategically placed perforations for efficient heat transfer. By evenly distributing heat, they enable precise plastic shaping and ensure consistent product quality and production efficiency.

Cartridge Heater

Cartridge heaters are indispensable in plastic converting machine testing. These compact heating elements, often made of stainless steel, provide controlled and uniform heat. Inserted into the machine, cartridge heaters ensure optimal temperature distribution, enabling precise plastic melting and molding processes with enhanced productivity and reliability.

All Type Cables

All types of cables are employed in plastic converting machine testing to establish connections and transmit signals between different components. These cables include power cables, communication cables, and sensor cables, ensuring reliable and efficient communication and operation of the testing equipment.

All Type PLCs

PLCs (Programmable Logic Controllers) of various types are utilized in plastic converting machine testing. These electronic devices control and automate the machine’s operations, including temperature, speed, pressure, and other parameters, ensuring accurate and efficient performance while maintaining quality standards in the plastic conversion process.

All Type Switch Gears

Switch gears are utilized in plastic converting machine testing to control and protect electrical circuits. They enable the operator to safely switch power on/off, regulate voltage levels, and safeguard the machinery from electrical faults, ensuring safe and efficient testing operations in the plastic converting process.

Anilox Roller

An anilox roller is a key component in plastic converting machine testing. It transfers a controlled amount of ink or coating onto the doctor blade, which then applies it to the printing or coating rolls. This ensures consistent and precise ink or coating distribution for optimal print quality.

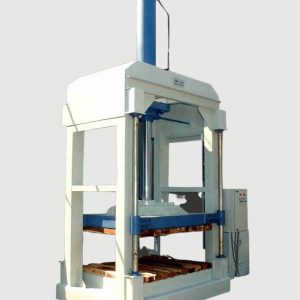

Bale Press Machine

A bale press machine is a specialized equipment used in plastic converting processes. It compresses plastic materials into compact bales for easy storage, transportation, and recycling. It maximizes efficiency, minimizes space requirements, and enhances the overall management of plastic waste in the converting industry.

Ball Shaft

The Ball Shaft is a key component utilized in slitting machines. It provides smooth rotation and stability for various machine functions, including serving as a quick lock mechanism for securely holding and releasing paper cores during the converting process.

Banana Roller

The Banana Roller is a valuable tool in plastic converting machine testing. Its curved shape and smooth surface enable it to guide and support the plastic material, preventing wrinkles, creases, or any surface defects during the converting process, ensuring high-quality output.

Bearings

High-performance bearings are essential in plastic converting machine testing. These bearings are specifically designed to withstand heavy loads, high speeds, and harsh operating conditions. They undergo rigorous testing to ensure optimal performance, precision, and durability, contributing to the efficient and reliable operation of plastic converting machines.

Blowers

Blowers are mechanical devices used in various industrial applications, including plastic converting. They generate a high-velocity airflow for processes such as drying, cooling, or exhausting. By providing directed air movement, blowers aid in efficient material handling and help maintain optimal conditions during plastic converting operations.

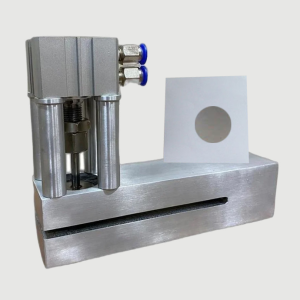

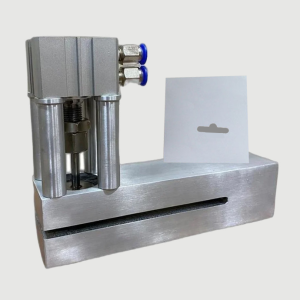

Hole Punch

A versatile tool for creating holes, the hole punch is essential for enhancing air circulation in various applications such as nursery bags and fruit bags. It promotes optimal ventilation, aiding in the growth and preservation of plants and fruits.

Butterfly Punch

The butterfly punch is a compact and portable tool designed for creating charming butterfly-shaped cutouts. Perfect for embellishing small items like pens and bags, it adds a whimsical touch to your belongings, allowing them to hang with a delightful and playful flair.

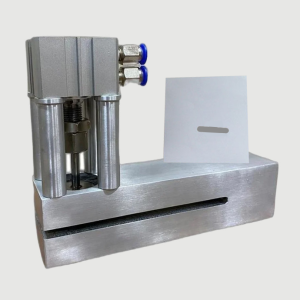

V Notch

The “V-notch” is commonly used in plastic converting machines to facilitate precise and consistent bag tearing. The machine incorporates the V-notch mechanism, which creates a uniform cut or score along the bag’s edge. This enables easy and accurate tearing during the conversion process, ensuring smooth and efficient production of plastic bags.

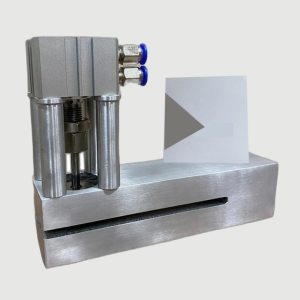

D Cut

The “D-cut” is widely used in plastic converting machines due to its effectiveness in creating secure and reliable handles on plastic bags. By incorporating the D-cut mechanism, the machine can accurately and efficiently cut out the distinctive D-shaped openings in bags, providing convenient and sturdy handles for easy carrying and transportation of various goods. This feature enhances the usability and functionality of the plastic bags produced by the machine.

Square Punch

The “Square punch” is utilized in plastic converting machines to create precise and uniform square-shaped cutouts in plastic materials. These square punches are commonly used for various purposes, including creating openings for windows, displays, or decorative elements in plastic products. The square punch ensures consistent and accurate cuts, enhancing the aesthetic appeal and functionality of the final plastic products produced by the machine.

Ceramic Roller

Ceramic rollers are widely used in plastic converting machine testing. These rollers offer excellent heat resistance, wear resistance, and smooth surface properties. They ensure precise material handling, minimize friction, and provide accurate performance evaluation during testing processes, contributing to overall operational efficiency.

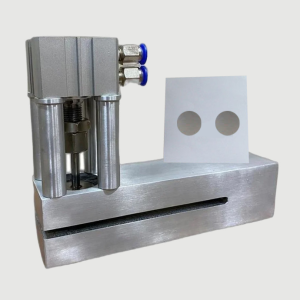

Round Cut Punch

The “Round Cut Punch” finds its purpose in plastic converting machines for creating circular or round-shaped cutouts in plastic materials. These round cut punches are commonly used for applications such as creating openings for bottle caps, lids, or circular windows in plastic products. The round cut punch ensures precise and uniform cuts, contributing to the functionality, design, and visual appeal of the plastic products manufactured by the machine.

Change Over Switch

Changeover switches are used in plastic converting machine testing to facilitate easy switching between different power sources or circuits. They allow operators to quickly transition between power supplies, ensuring uninterrupted testing and enabling the machine to adapt to different electrical configurations or requirements.

Wicket Hole Punch

The “Wicket Hole Punch” serves a specific purpose in plastic converting machines by creating holes or slots in plastic materials that are used for wicketing. Wicketing refers to the process of attaching multiple bags together on a wicket, allowing for easy handling and packaging. The Wicket Hole Punch ensures precise and consistent holes or slots, enabling smooth wicketing of plastic bags during the manufacturing process. This feature enhances the efficiency and convenience of packaging operations in industries such as food, retail, and manufacturing.

Chiller

The Chiller plays a critical role in extrusion machines. It is responsible for cooling the water used in the machine, controlling and maintaining the temperature of the cooling water to prevent overheating and ensure optimal operating conditions for the converting process.

Star Punch

The “Star Punch” is employed in plastic converting machines to create star-shaped cutouts in plastic materials. This feature is commonly used for decorative purposes, adding an appealing and distinctive design element to plastic products. The Star Punch ensures precise and uniform cuts, enhancing the aesthetic value and visual appeal of the final plastic products manufactured by the machine. It is particularly useful in industries where decorative or creative designs are desired, such as crafts, party supplies, and promotional items.

Chiller

A chiller is a refrigeration device used in plastic machinery. It removes heat from industrial equipment, such as extruders or molds, by circulating chilled water or refrigerant. Chillers maintain precise temperature control, ensuring optimal performance and quality.

Coating Roller

Coating rollers are an integral part of plastic converting machine testing. These rollers apply a thin, uniform coating on plastic substrates, ensuring precise testing and consistent results. By facilitating smooth and controlled coating application, they contribute to the quality and efficiency of the plastic conversion process.

Compressor

A compressor is a mechanical device used to increase the pressure of gases or air. It is commonly used in various industrial applications, including plastic converting. Compressors provide a continuous supply of compressed air, enabling pneumatic operations and powering pneumatic tools and machinery in the plastic converting process.

Connectors

Connectors are essential components in plastic converting machine testing as they establish electrical and mechanical connections between different parts and components. They enable the seamless integration of sensors, actuators, power supplies, and control systems, ensuring reliable data transmission and efficient operation during testing processes.

Continous Band Sealer

A continuous band sealer is a specialized machine used in plastic converting machine testing. It seals plastic bags or pouches with a continuous band of heat, ensuring airtight and secure packaging. It enhances product integrity, prevents contamination, and facilitates efficient testing processes in the plastic converting industry.

Conveyor Belts

Conveyor belts are integral in plastic converting machine testing. These belts facilitate the smooth and continuous movement of materials or products during the testing process. They ensure efficient transfer, precise positioning, and reliable handling, enabling thorough assessment of the machine’s functionality and performance.