-

Empty cart

No products in the cart.

Return to Shop

Filters

Showing 61–120 of 152 results

See

Conveyor Systems

Conveyor systems are integral to plastic converting machine testing, providing efficient material handling. They consist of belts or rollers that move plastic materials or products along a designated path, facilitating continuous testing processes. Conveyor systems ensure smooth flow, accurate positioning, and seamless integration of plastic components during testing operations.

Cooling Tower

The Cooling Tower is a crucial element in extrusion machines. It is part of the cooling water plant, responsible for dissipating heat from the water used in the machine, ensuring optimal temperature control and preventing overheating during the converting operations. It promotes efficient and consistent cooling performance.

Cooling Towers

Cooling towers are crucial components of industrial processes, including plastic converting. They remove excess heat from equipment and machinery by circulating and cooling water. By dissipating heat, cooling towers ensure optimal operation, prevent overheating, and maintain efficient performance in plastic converting operations.

Core Cutter Machine

A core cutter machine is a specialized tool used in plastic converting machine testing. It precisely cuts and shapes cores, which are cylindrical tubes used for winding plastic films or materials. This machine ensures accurate and consistent core dimensions, facilitating efficient handling and storage during the testing process.

Corona Treater

The Corona Treater is a key component in extrusion machines. It operates within a width range of 500mm to 2300mm and utilizes pneumatic operation along with the latest IGBT technology system. It enhances surface tension on plastic films, enabling better adhesion of inks, coatings, and adhesives for improved printability and product quality.

Dies

Recycle Your Trim Waste On Extruder It Self

The Trim Grinder is a tool employed in plastic converting machine testing for recycling trim waste directly on the extruder. It efficiently grinds and processes the trim waste, allowing it to be reintroduced into the extrusion process, minimizing waste and maximizing material utilization.

Digital Micromters

Digital micrometers are indispensable tools in plastic converting machine testing. They provide precise measurements of material thickness, dimensions, and tolerances. With their digital readout and high accuracy, they enable quality control and ensure that the plastic conversion process meets the desired specifications.

Ditigal Thickness Gauge Meter

A digital thickness gauge meter is an essential tool used in plastic converting machine testing. It accurately measures the thickness of plastic sheets, films, or other materials during production. This allows for precise control and quality assurance of the plastic conversion process, ensuring desired thickness specifications are met.

Doctor Blades

Doctor blades are utilized in plastic converting machine testing to control the application of inks or coatings. They act as flexible, precise scraping tools, removing excess material from the printing or coating rolls, ensuring uniform coverage and high-quality results.

Double Side Mounting Tape For Flexo

Double-sided mounting tape for flexo is extensively tested in plastic converting machines. These machines evaluate the tape’s adhesive strength, flexibility, and compatibility with flexographic printing processes. The tape undergoes rigorous testing to ensure optimal performance and reliable adhesion in plastic converting applications.

Drivers AC/DC/ Servo

AC/DC/Servo drivers are integral to plastic converting machine testing. They regulate the power supply to AC, DC, or servo motors, providing precise control over speed, torque, and positioning. These drivers ensure smooth and accurate operation, enabling efficient and reliable testing in the plastic converting process.

Drum Stacker

A drum stacker is a specialized equipment used in plastic converting machine testing. It is designed to safely lift, transport, and stack drums or barrels containing plastic materials. This facilitates efficient material handling during the testing process, ensuring smooth and organized workflow in the laboratory or workshop.

Duck Pipes

Duck Pipes are specially designed plastic conduits used for testing purposes in plastic converting machines. These pipes facilitate the flow of molten plastic, allowing technicians to assess the machine’s performance, accuracy, and functionality.

Edge Guide

The Edge Guide is an essential tool employed in plastic converting machine testing. It ensures proper alignment and positioning of the material, allowing for precise cutting, folding, and other converting operations to maintain consistent quality and accuracy.

Edge Guide

The Edge Guide is an essential component employed in plastic blown film machine to ensure proper winding on the unwinder unit. It precisely guides the plastic material, aligning the edges to achieve uniform winding and prevent any misalignment or material wastage during the production process.

Edge Guide

Edge guides are likely employed in plastic converting machine testing. These guides help ensure precise alignment and control of the plastic material as it passes through the machine. They enhance accuracy, minimize material wastage, and assist in evaluating the machine’s performance during testing processes.

Edge Guide (Electronics System & Hydraulic System)

The Edge Guide is a critical feature utilized in plastic converting machines for maintaining precise alignment and positioning of plastic materials during the conversion process. The machine employs two types of edge guide systems: an electronic system and a hydraulic system.

The electronic edge guide utilizes a DC motor with a controlling display to automatically adjust and maintain the desired alignment of the plastic material. This system constantly monitors and adjusts the position of the material to ensure accurate processing and minimize waste. It provides real-time feedback and control, allowing for precise and consistent results.

On the other hand, the hydraulic edge guide employs a hydraulic cylinder mechanism to adjust and control the position of the plastic material. This system utilizes hydraulic pressure to move the edge guide mechanism, ensuring precise alignment and tension control. It provides reliable and robust performance in maintaining the alignment of wide plastic materials.

Both the electronic and hydraulic edge guide systems play a crucial role in the plastic converting machine by enabling accurate positioning and alignment of the plastic material. They help achieve consistent and high-quality output by minimizing material waste, reducing errors, and ensuring efficient production processes.

Encoders

Encoders are essential in plastic converting machine testing to accurately measure position, speed, and direction of moving components. They provide precise feedback, enabling precise control and synchronization of various machine movements, ensuring optimal performance and quality in the plastic converting process.

Film folding device

The film folding device is utilized in plastic converting machines to precisely fold plastic films, sheets, or materials during the conversion process. It ensures accurate and uniform folding, enabling the creation of various products such as bags, packaging materials, or other folded plastic items with consistent and desired dimensions. The size ranges from 1200mm to 1600mm in width, into tube forms. With a speed range of 30mtr/min to 60mtr/min, it ensures efficient and precise folding of plastic materials. The stand-alone folder streamlines the folding process, allowing for consistent and neatly folded plastic bags and pouches at high production speeds. We have our own special design Folding System for accurate folding without any creasing.

Foot Sealer

A foot sealer is a manual sealing device commonly used in plastic converting machine testing. It operates by pressing a foot pedal to activate the heat sealing mechanism, securely sealing plastic bags or pouches. It provides convenience, ease of use, and reliable sealing for testing purposes in the plastic converting industry.

Gears

Gears are indispensable in plastic converting machine testing. These mechanical components enable power transmission, torque conversion, and precise rotational movement within the machinery. Gears ensure accurate speed control, efficient force distribution, and reliable performance evaluation during testing processes.

Gears

In the testing phase of a plastic converting machine, gears are examined for their functionality and durability. These gears play a crucial role in the machine’s operation, ensuring the efficient conversion of plastic materials into desired products.

Mark Sensors

Mark sensors are devices used in plastic converting machine testing to detect and interpret marks or patterns on plastic materials. They enable accurate positioning, alignment, and quality control during the conversion process, ensuring precise cutting, printing, or other operations.

Hand Sealer

A hand sealer is a portable sealing tool used in plastic converting machine testing. It features a handheld design and utilizes heat to seal plastic bags or pouches. With its compact size and simple operation, it provides convenient and efficient sealing for testing purposes in the plastic converting industry.

Header Sealer

The “Header Sealer” is utilized in plastic converting machines for sealing header cards or headers onto plastic bags or packaging. It ensures secure attachment, providing a professional and presentable display and allowing for convenient hanging or presentation of the packaged products.

Heater Zone

Heater zones are essential components in plastic converting machine testing. These zones consist of heating elements that provide controlled and uniform heat to specific sections of the machine. They enable the testing of temperature-sensitive plastic materials, ensuring proper heating and evaluating the machine’s thermal performance.

Hopper Loader

The Hopper Loader is used in extrusion machines. It enables automatic feeding of granules into the extruder hopper, ensuring a continuous and consistent supply of material for efficient and uninterrupted production in the extrusion process.

Hopper Magnet

The Hopper Magnet is a crucial component in plastic converting machine testing. It is placed in the hopper or feeding system to capture and remove metal contaminants from the plastic materials, ensuring product quality, equipment protection, and preventing potential damage during the converting process.

Hot Dryer

The Hot Dryer is an essential element in extrusion machine. It utilizes heat to efficiently remove moisture from plastic materials, ensuring optimal quality and performance. It is particularly effective in eliminating moisture in granules or pellets used in the converting process.

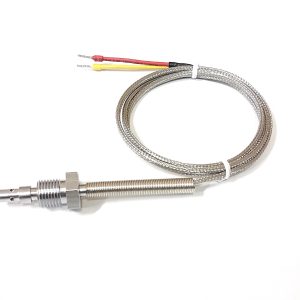

J Type Thermocouples

J type thermocouples are ingeniously employed in plastic converting machine testing. These thermocouples exploit the voltage produced by the junction of different metals to measure temperature. By incorporating J type thermocouples, precise temperature control enhances plastic conversion processes, ensuring impeccable output quality and efficiency.

K Type Thermocouples

K type thermocouples revolutionize temperature measurement. By harnessing the voltage generated from the union of dissimilar metals, these thermocouples accurately monitor and regulate temperature during the conversion process, optimizing plastic production with precision and efficiency.

PT-100 (Platinum Resistance Temperature Detector) Thermocouples

PT-100 (Platinum Resistance Temperature Detector) is commonly used in plastic converting machine testing. It is a temperature sensor that utilizes a platinum element to measure temperature with high accuracy and stability, allowing for precise temperature monitoring and control during the testing process.

RTD (Resistance Temperature Detector) Thermocouples

RTD (Resistance Temperature Detector) is a type of sensor used in plastic converting machine testing to measure temperature accurately. It consists of a wire coil or thin film that changes resistance with temperature variations, providing precise temperature data for monitoring and control purposes during testing.

Knurling Roller

The Knurling Roller is a vital tool used in extrusion machines. It features a patterned surface that facilitates enhanced grip and traction on plastic materials, ensuring efficient feeding and traction control. Additionally, it is employed for online knurling on extruder plants to create surface textures or patterns on plastic products.

Laser Postion System

The Laser Position System is a precision tool employed in slitting machines. It utilizes laser technology to accurately determine and adjust the positioning of the core on the rewinder, ensuring precise alignment for efficient winding and unwinding of plastic materials.

Line Guide

The Line Guide is a standard component utilized in plastic converting machine testing. It aids in guiding the material along a straight path, ensuring uniformity and precision during cutting, printing, laminating, or any other converting processes for optimal results.

Logo Printing Machine

The Logo Printing Machine is utilized in extrusion machines testing for applying single-color logos onto plastic materials. It integrates with the extruder machine, allowing precise and efficient printing, enhancing product branding and aesthetics in the plastic conversion process.

Magnetic Roller

Magnetic rollers are highly beneficial in plastic converting machine testing. These rollers incorporate magnetic fields to attract and separate metallic impurities from plastic materials, ensuring purity and quality control. They enhance the testing process by removing contaminants and ensuring optimal material integrity.

MCB MCCB ELCB

MCB (Miniature Circuit Breaker), MCCB (Molded Case Circuit Breaker), and ELCB (Earth Leakage Circuit Breaker) are electrical protection devices used in plastic converting machine testing. They automatically detect and interrupt electrical faults, such as overloads, short circuits, or earth leakages, safeguarding the machine and preventing damage or accidents.

Mechanical Shaft

The Mechanical Shaft is a vital component in plastic converting machine testing. It provides a secure and adjustable connection between the machine and various components like rollers or blades, facilitating smooth and precise movements, ensuring accurate and efficient processing of plastic materials.

Motor AC/DC

AC/DC motors are key components in plastic converting machine testing. AC motors convert electrical energy into rotational motion, while DC motors use direct current. These motors provide power for various machine functions, such as driving conveyor belts, rollers, or other mechanical components during testing operations.

Nichrom Wires

Discover high-quality Nichrome wires for plastic converting machine testing. These durable and heat-resistant wires are designed to withstand demanding conditions, ensuring accurate and efficient testing. Enhance your testing process with reliable Nichrome wires that deliver reliable results every time.

Offline Punch Machine

The Offline Punches Machine in a plastic converting machine is a versatile tool that accommodates various punching operations, including the D-punch, hole punch, and t-shirt punch. It enables manufacturers to add custom shapes, holes, and unique designs to plastic materials during secondary conversion processes.

With the D-punch feature, the machine can create precise D-shaped cutouts in plastic products, offering functionality and aesthetic appeal. The hole punch function allows for the creation of regular holes in different sizes, enabling ventilation or attachment points as needed. Additionally, the t-shirt punch capability enables the machine to create specific cuts or shapes typically used for hanging t-shirts or garments.

By incorporating the D-punch, hole punch, and t-shirt punch functionalities, the Offline Punches Machine expands the creative possibilities and customization options for plastic products. It empowers manufacturers to produce unique and tailored plastic items with enhanced functionality, design, and branding opportunities.

Oil Seals

Oil seals are essential components used in plastic converting machines to prevent leakage of oil and protect the machinery from contaminants. They provide a tight seal between moving parts, ensuring smooth operation and extending the machine’s lifespan.

Packaging Tapes

Packaging tapes undergo rigorous testing in plastic converting machines. These machines evaluate the tapes’ strength, adhesion, and durability, ensuring they meet quality standards. The tapes are subjected to various mechanical and environmental conditions to assess their performance and suitability for packaging applications.

Pallate Stacker

A pallet stacker is a versatile industrial tool used for lifting, moving, and stacking pallets in plastic converting machine testing. It provides efficient material handling, streamlines workflow, and optimizes storage space, making it indispensable for smooth and organized operations in the testing process.

Perforation Wheel / Blades

The Perforation Wheel/Blades are used in plastic converting machines to create precise perforations or cut lines on plastic materials. This enables easy tear-off sections in plastic bags or packaging, enhancing functionality and convenience.

Pid And Digital Temp. Controller

PID (Proportional-Integral-Derivative) and digital temperature controllers are essential in plastic converting machine testing. They precisely regulate and maintain the temperature of heating elements or zones, ensuring optimal process conditions and consistent quality during the plastic converting process.

Pin Perforation Roller

The Pin Perforation Roller is essential in plastic converting machines to create precise and uniform perforations on plastic materials. It enables a controlled ventilation or perforated patterns, enhancing the functionality and versatility of plastic bags, packaging or other plastic products.

Pneumatic Break

The Pneumatic Brake is a commonly used feature in plastic converting machine testing. It utilizes pneumatic pressure to control the tension of the material, allowing for precise control and adjustment during unwinding or rewinding processes, ensuring smooth and consistent operation.

Pneumatics All Types

Pneumatics, encompassing various types of pneumatic components, play a crucial role in plastic converting machine testing. Utilizing compressed air, they control actuators, valves, and other devices, facilitating precise movement, gripping, and positioning of materials, ensuring efficient and accurate testing in the plastic converting process.

Power Distribution Panel

A power distribution panel is an electrical enclosure that serves as a central hub for distributing electricity to various devices and equipment in a facility or industrial setting. It safely divides and controls power supply, ensuring efficient and reliable distribution throughout the system.

Power Supply

The power supply used in plastic converting machine testing is an electrical device that provides the necessary electrical energy to operate the machine. It ensures a stable and consistent power source, enabling the machine to function efficiently and accurately during testing.

Printing Cylinder

Printing cylinders is used in plastic converting machine testing. These cylinders feature engraved or etched patterns that transfer ink onto the plastic material, allowing for precise and consistent printing. They enable accurate evaluation of printing quality and performance during testing processes.

Pulley

Pulleys are crucial components in plastic converting machine testing. Designed with precision, these pulleys ensure smooth and efficient rotation of belts or other mechanical components, allowing accurate evaluation of power transmission, tension control, and overall performance of the machine during testing processes.

Retrofitting with Servo Kits

Retrofitting with Servo Kits in plastic converting machines refers to the process of upgrading or modernizing the machine’s existing microcontroller system by replacing it with a new high-speed controller PLC system integrated with servo technology.

The retrofitting process involves removing the outdated microcontroller system and installing a new PLC (Programmable Logic Controller) system that offers improved functionality, performance, and control. The new PLC system is equipped with servo technology, which utilizes high-precision servo motors to provide accurate and precise control over various machine movements, such as cutting, sealing, or feeding.

By retrofitting the machine with servo kits and a new high-speed controller PLC system, manufacturers can significantly enhance the machine’s capabilities and productivity. The servo technology enables better synchronization, faster response times, and more precise positioning, resulting in improved accuracy, speed, and efficiency of the plastic converting process.

Additionally, the new PLC system provides advanced features, such as comprehensive programming options, enhanced diagnostics, and user-friendly interfaces. This allows operators to have better control over the machine’s operations and facilitates easier adjustments, troubleshooting, and optimization of the production process.

Overall, retrofitting with servo kits and a new high-speed controller PLC system in plastic converting machines enables manufacturers to upgrade their equipment, unlocking improved performance, accuracy, and efficiency, thereby maximizing productivity and achieving higher quality output.

Rotary Cutter System

The Rotary Cutter System is a vital feature utilized in plastic converting machine testing. It employs a rotating cutter mechanism to precisely cut plastic materials, ensuring accurate and clean cuts for various applications in the converting process.

Rubber Roller

A rubber roller is an essential element in plastic converting machine testing. It is responsible for guiding and conveying the plastic material through various stages of the machine. The rubber surface provides friction and stability, ensuring smooth and consistent material movement for accurate processing.

Rubber Strips

Rubber strips are suitable for testing in plastic converting machines. These strips offer flexibility, durability, and high friction properties, ensuring accurate performance evaluation and compatibility assessment within the machinery’s operational parameters.