-

Empty cart

No products in the cart.

Return to Shop

Filters

Showing 121–152 of 152 results

See

Safety Chuck

The Safety Chuck is an integral component utilized in plastic converting machine testing. It provides a secure and reliable gripping mechanism for holding and rotating the rolls of material, ensuring stable and safe operation during unwinding and rewinding processes.

Screen Changer

The Screen Changer is a valuable tool in plastic converting machine testing. It effectively filters out impurities and contaminants from the molten plastic, ensuring a clean and high-quality output. It allows for easy and efficient screen replacement to maintain uninterrupted production during the testing process.

Screw And Barrels

Screws are elements in extrusion machines, specifically barrels screws ranging from 35mm to 75mm in diameter. They are designed as bi-metallic or nitrided, ensuring effective and high-performance operation, resulting in better output and the production of high-quality films.

Sensors

Sensors are utilized in plastic converting machine testing to monitor various parameters and ensure proper functioning. They detect factors like temperature, pressure, speed, position, and presence of objects, providing real-time feedback for control and optimization, ensuring reliable and accurate testing results.

Silicon Sleeves

Silicon sleeves are extensively utilized for testing purposes in plastic converting machines. With their heat resistance, excellent insulation properties, and smooth surface, these sleeves provide effective protection, seamless operation, and precise evaluation of the machine’s performance and compatibility.

SSR

Enhance your plastic converting machine testing with top-notch SSRs (Solid State Relays). These reliable electronic switches provide precise control and seamless operation, ensuring optimal performance. Choose high-quality SSRs for accurate and efficient testing of your plastic converting machines.

Stand Alone Folder

Folding Film Sheetform To Tube Form Widht 1200Mm To 1600Mm Speed 30Mtr/Min To 60Mtr/Min

The “Stand alone folder” is a crucial component in plastic converting machines used for folding film sheets, ranging from 1200mm to 1600mm in width, into tube forms. With a speed range of 30mtr/min to 60mtr/min, it ensures efficient and precise folding of plastic materials. This feature contributes to the overall functionality and quality of the plastic products, including bags or packaging materials, produced by the machine. The stand-alone folder streamlines the folding process, allowing for consistent and neatly folded plastic products at high production speeds.

Static Brush

Static brushes are effectively utilized in printing and lamination machines to remove static charges on film. These brushes consist of conductive bristles that neutralize and dissipate static electricity, preventing unwanted adhesion, sticking, or misalignment of the film during the testing process.

Static Electrode And Unit

Static electrodes and units are extensively used in printing and lamination machines to eliminate static charges on film. These devices generate ionized air or apply direct charges to neutralize static electricity, ensuring the film remains static-free during the testing process, preventing issues such as misfeeding or improper winding.

Static Eliminators

Static eliminators are crucial in plastic converting machine testing. These devices neutralize static electricity, preventing issues like material sticking, misalignment, and electrostatic discharge. By effectively eliminating static charges, they ensure smooth and efficient operation during the testing process of plastic converting machines.

Static Mixer

Static mixers are essential in plastic converting machine testing. These devices efficiently blend and homogenize plastic materials by dividing and recombining them through a series of stationary mixing elements. They ensure consistent material composition and quality control during the testing process.

Strech Wrapping Machine

A stretch wrapping machine is a specialized equipment used in plastic converting machine testing. It wraps plastic products or materials with a stretchable film, ensuring secure packaging and protection. This machine facilitates efficient handling, storage, and transportation of plastic items during the testing process.

Teflon Cloths

Discover Teflon cloths for plastic converting machine testing. These specialized cloths offer exceptional heat resistance and non-stick properties, ensuring smooth material flow and preventing sticking. Enhance your testing accuracy and efficiency with high-quality Teflon cloths for optimal results.

Teflon Dam

Teflon dams are utilized in plastic converting machine testing. These dams, made of Teflon material, are strategically placed to control the flow and containment of molten plastic within the machine. They provide excellent heat resistance, chemical resistance, and prevent leakage or overflow during testing processes.

Tension Controller

A tension controller is an essential component used in plastic converting machine testing. It regulates and maintains the appropriate tension of the plastic material during the conversion process, ensuring smooth and accurate operations.

Timing Belts

Timing belts are essential in plastic converting machine testing. These belts feature toothed surfaces that engage with corresponding pulleys, providing precise synchronization and accurate positioning of machine components. They ensure reliable power transmission, smooth operation, and precise evaluation of the machine’s performance during testing.

Torque Controller

A torque controller is utilized in plastic converting machine testing to ensure precise and consistent torque application. It helps achieve proper assembly, prevent over-tightening or under-tightening, and ensures the desired quality and functionality of plastic components during the testing process.

Transfer Roller

The transfer roller, used in plastic converting machine testing, is a crucial component that facilitates the transfer of materials during the manufacturing process. It ensures smooth and efficient movement of plastic through the machinery, enabling accurate and consistent production.

Trim Grinder

The Trim Grinder is a tool employed for recycling trim waste directly on the extruder. It efficiently grinds and processes the trim waste, allowing it to be reintroduced into the extrusion process, minimizing waste and maximizing material utilization.

Trim Winder

A trim winder is an essential component of plastic converting machine testing. It collects and winds the excess or trimmed plastic material produced during the testing process. This facilitates neat and organized waste management, ensuring a clean and efficient testing environment.

Trim Winder

The Trim Winder is a crucial component of slitting machines. It efficiently handles trim widths ranging from 5 to 40mm at a speed of 300mtr/min, making it ideal for slitting operations.

Twin Sealer

The Twin Sealer is employed in plastic converting machinery for the purpose of achieving thicker and stronger seals in bags, particularly those with widths of 5mm, 10mm, and similar dimensions. This specialized sealer ensures enhanced sealing performance, allowing for reliable and durable closures in heavy-duty or thicker plastic bags.

Ultrasonics

Ultrasonics is employed in plastic converting machines for various applications, including squeezing and knurling. Ultrasonic technology utilizes high-frequency vibrations to generate heat and pressure, allowing for effective bonding, cutting, or sealing of plastic materials.

In the context of squeezing applications, ultrasonics can be utilized to join or seal plastic components together. The high-frequency vibrations create localized heat at the contact points, causing the plastic to melt and fuse, resulting in a strong and secure bond. This technique is commonly used in applications such as bag sealing, creating airtight closures, or bonding plastic parts together.

Furthermore, the knurling application of ultrasonics involves creating textured or patterned surfaces on plastic materials. The high-frequency vibrations, when applied to the desired area, can imprint or emboss patterns onto the plastic surface, enhancing grip, aesthetics, or functionality. Knurling is often employed in applications such as improving the grip of handles, creating decorative designs, or providing anti-slip surfaces.

By incorporating ultrasonics in the plastic converting machine, manufacturers can achieve precise and efficient squeezing and knurling processes. The technology offers fast and reliable bonding, sealing, or surface modification of plastic materials, contributing to the overall quality, functionality, and appearance of the final plastic products.

Unwinder Stand with Edge Guide System

The Unwinder stand with edge guide system serves a crucial purpose in plastic converting machines for handling and aligning plastic materials during the conversion process. This component is specifically designed to unwind plastic rolls of varying widths, ranging from 600mm to 1500mm, while ensuring proper edge alignment.

The unwinder stand incorporates an edge guide system that can be either electronic or hydraulic, depending on the specific machine configuration. The electronic edge guide utilizes advanced technology, such as sensors and a controlling display, to automatically adjust and maintain the alignment of the plastic material as it unwinds. This ensures precise and consistent positioning, minimizing waste and ensuring smooth processing.

Alternatively, the hydraulic edge guide system employs hydraulic cylinders to adjust and control the alignment of the plastic material. By applying hydraulic pressure, the system ensures accurate edge alignment and tension control, guaranteeing the stability and uniformity of the material during the unwinding process.

The integration of the unwinder stand with an edge guide system in plastic converting machines enables efficient handling and alignment of plastic materials of different widths. This feature plays a crucial role in maintaining proper tension, alignment, and control of the plastic material, ultimately contributing to high-quality output, reduced waste, and improved production efficiency.

V Belts

V belts used in plastic converting machine testing. These specially designed belts offer excellent traction, high power transmission capabilities, and resistance to wear and tear. They ensure smooth and efficient operation while assessing the machine’s performance, stability, and reliability during testing.

Vaccum Pump

A vacuum pump is an essential tool used in plastic converting machine testing. It creates a vacuum or negative pressure to remove air or gases from a system. In testing, vacuum pumps aid in achieving proper material adhesion, eliminating bubbles, and ensuring the desired quality of plastic products.

Water Pump

A water pump is a device used to circulate or move water in various applications. In plastic converting machine testing, water pumps facilitate cooling and temperature control by providing a consistent flow of water to regulate equipment temperature and maintain optimal operating conditions.

Web Camera

In printing and lamination machines, a web camera is employed for the correction of printing registration. The camera captures real-time images of the printing process, allowing for precise alignment and adjustment to ensure accurate registration and high-quality printed output.

Winders (Single Station or Double Station)

Winders, whether Single Station or Double Station, are essential in plastic converting machine testing. They facilitate the precise winding of plastic materials into rolls, ensuring proper tension control, alignment, and consistent winding quality, enabling efficient handling and further processing of the converted products.

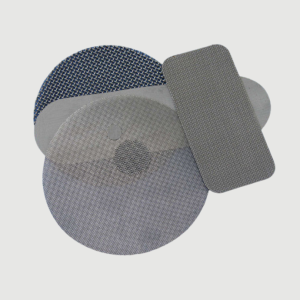

Wire Mesh

Explore durable wire mesh for plastic converting machine testing. This versatile mesh provides excellent support and stability during testing processes, ensuring consistent and accurate results. Enhance your testing efficiency with high-quality wire mesh designed specifically for plastic converting machines.

Works Shops Machinery

Workshop machinery used in plastic converting machine testing comprises specialized equipment for production and quality assurance. It includes extrusion machines for plastic melting and shaping, injection molding machines for creating plastic parts, and cutting machines for precision trimming. These machinery ensure efficient and accurate plastic conversion processes in workshop settings.

Works Shops Tools

Workshop tools are essential for various tasks in a workshop environment. They include power tools like drills, saws, and sanders for cutting and shaping materials. Hand tools such as wrenches, hammers, and screwdrivers aid in assembly and maintenance. These tools facilitate efficient and precise work in workshops.