Ultrasonics is employed in plastic converting machines for various applications, including squeezing and knurling. Ultrasonic technology utilizes high-frequency vibrations to generate heat and pressure, allowing for effective bonding, cutting, or sealing of plastic materials.

In the context of squeezing applications, ultrasonics can be utilized to join or seal plastic components together. The high-frequency vibrations create localized heat at the contact points, causing the plastic to melt and fuse, resulting in a strong and secure bond. This technique is commonly used in applications such as bag sealing, creating airtight closures, or bonding plastic parts together.

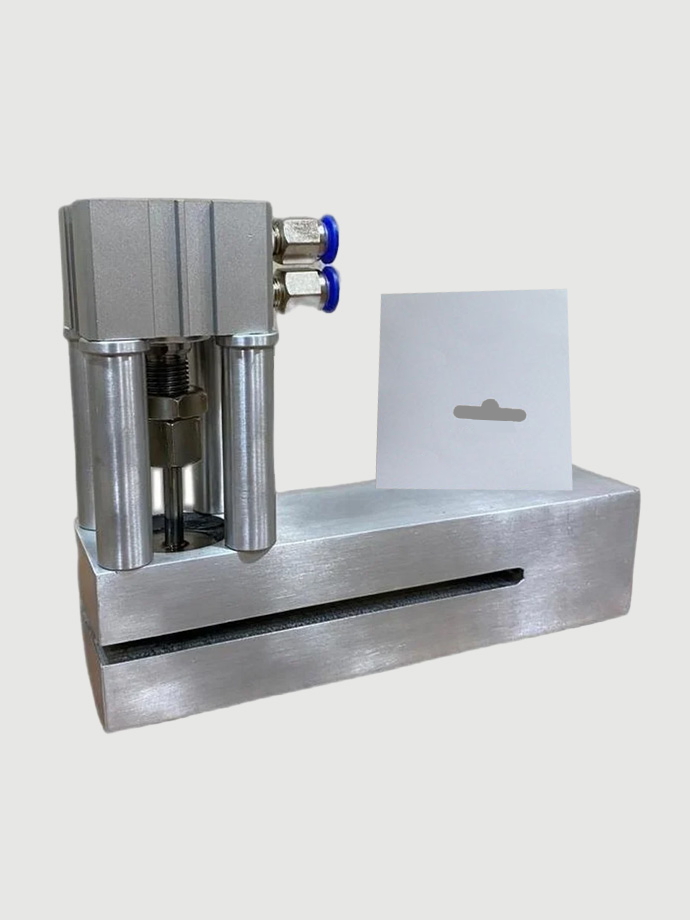

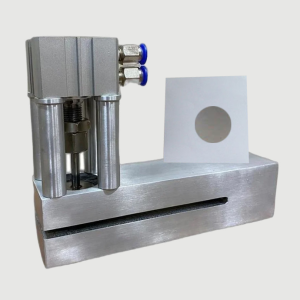

Furthermore, the knurling application of ultrasonics involves creating textured or patterned surfaces on plastic materials. The high-frequency vibrations, when applied to the desired area, can imprint or emboss patterns onto the plastic surface, enhancing grip, aesthetics, or functionality. Knurling is often employed in applications such as improving the grip of handles, creating decorative designs, or providing anti-slip surfaces.

By incorporating ultrasonics in the plastic converting machine, manufacturers can achieve precise and efficient squeezing and knurling processes. The technology offers fast and reliable bonding, sealing, or surface modification of plastic materials, contributing to the overall quality, functionality, and appearance of the final plastic products.